Sorbothane stands out as the premier vibration dampening material for imaging, outperforming standard rubber and foam padding with its superior damping coefficient. It absorbs energy like a viscous liquid, conforming to your equipment while returning to its original shape after impact. For high-magnification imaging (3,000-5,000x), this material effectively eliminates wave-like artifacts caused by low-frequency vibrations. Thicker layers work best for heavier equipment and lower frequencies, potentially reducing vibration amplitude by up to 99%.

The Science Behind Vibration Interference in Imaging

When you’re capturing images at magnifications of 3,000 to 5,000 times, even the slightest vibration can dramatically compromise your results.

These disturbances manifest as wave-like artifacts in your live view, leading to blurred images and inaccurate measurements.

Low-frequency vibrations, particularly in the 1.5 to 3 Hz range, pose the greatest threat as they can resonate with your imaging equipment, amplifying the interference.

Low-frequency vibrations (1.5-3 Hz) are your worst enemies, creating resonance effects that dramatically amplify interference in precision imaging systems.

Your everyday environment is filled with vibration sources you mightn’t consider: nearby machinery, foot traffic, and even HVAC systems all contribute to the problem.

Effective vibration control is essential for high-precision imaging tasks.

Without proper isolation techniques, such as granite platforms or active dampening systems, external noise will continue to degrade your image quality and undermine measurement reliability.

Comparing Viscoelastic Materials for Camera Stabilization

Among various vibration dampening solutions available today, viscoelastic materials stand out as essential components for serious imaging applications. When comparing options, Sorbothane consistently outperforms traditional materials in vibration damping applications for cameras.

You’ll find Sorbothane’s unique properties allow it to flow like a viscous liquid when impacted, conforming to your equipment’s shape before returning to its original form. This superior viscoelasticity translates directly to sharper images by effectively converting vibration energy into heat.

| Material | Damping Coefficient | Customization |

|---|---|---|

| Sorbothane | Highest | Multiple sizes/shapes |

| Standard Rubber | Medium | Limited options |

| Foam Padding | Low | Easy to cut/shape |

Unlike alternatives, Sorbothane can be tailored to your specific setup, providing ideal protection for sensitive optics and electronics while minimizing distortion in your photography and videography work.

Sorbothane: Properties and Performance in Photography

As photographers seek ultimate image clarity, Sorbothane emerges as the premier vibration dampening solution in the market today. This remarkable viscoelastic material functions simultaneously as both liquid and solid, absorbing vibration energy that would otherwise compromise your shots.

Your vibration isolation system’s effectiveness depends largely on its dampening material, and Sorbothane’s superior damping coefficient outperforms alternatives. You’ll appreciate how it controls high-amplitude vibrations that threaten delicate optics and electronics.

What makes Sorbothane particularly valuable is its adaptability—available in various thicknesses and shapes to suit specific mounting needs.

After absorbing vibrations, it returns to its original form, ensuring continued protection during both operation and transport. This resilience preserves image quality and extends equipment life through consistent performance.

Elastomeric Compounds vs. Rigid Foam Solutions

The choice between elastomeric compounds and rigid foam solutions presents distinct performance trade-offs for vibration control in imaging systems.

When you’re designing a vibration isolation system’s components, elastomeric materials like Sorbothane offer superior damping characteristics by converting vibration energy into heat—a significant advantage for precision imaging equipment.

While rigid foams provide a lightweight, cost-effective option, they simply can’t match the damping coefficients of elastomers. You’ll find elastomeric compounds perform consistently across wider frequency ranges, particularly for problematic low-frequency vibrations that distort imaging results.

Additionally, elastomers can be custom-shaped to fit your specific equipment needs, conforming to irregular surfaces without gaps that might transmit unwanted vibrations.

Rigid foams, however, often leave contact points where vibrations can transfer directly to sensitive devices.

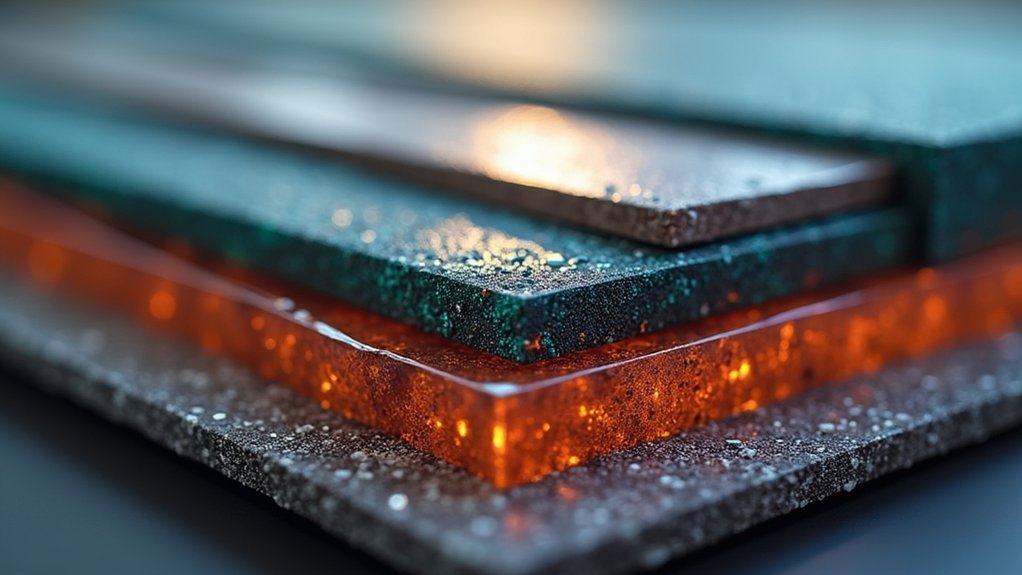

Multi-Layered Materials for Comprehensive Vibration Control

Multi-layered materials offer you superior vibration control by combining elastomeric layers with specialized viscoelastic compounds like Sorbothane in a progressive density arrangement.

You’ll achieve broader frequency protection through these strategically stacked materials, which can be custom-engineered to target the specific vibration frequencies affecting your imaging equipment.

The layered configuration not only enhances dampening capabilities across a wider spectrum but also improves thermal management by efficiently dissipating vibration energy as heat away from sensitive optics.

Multi-Layer Composition Benefits

When engineering ideal vibration control for imaging equipment, multi-layered materials stand out as superior solutions.

You’ll find these composite structures uniquely capable of addressing multiple vibration frequencies simultaneously, something single-material solutions simply can’t match.

The strategic combination of viscoelastic materials like Sorbothane with rigid substrates creates an excellent vibration isolation system.

Each layer serves a specific purpose: softer materials absorb high-frequency vibrations while denser components handle low-frequency disturbances that typically plague precision imaging.

Progressive Density Arrangements

Progressive density arrangements represent the pinnacle of vibration dampening technology for imaging applications.

These sophisticated systems utilize multiple layers of viscoelastic materials like Sorbothane, each with varying densities, to target and absorb specific vibration frequencies.

You’ll achieve superior vibration isolation by implementing these multi-layered solutions, which can deliver up to 99% isolation efficiency at vital low frequencies.

The strategic stacking of materials creates a thorough dampening effect that protects your sensitive imaging equipment from environmental disturbances.

What makes these arrangements particularly valuable is their customizability.

You can tailor the configuration to your specific equipment needs and environmental conditions, ensuring maximum protection against distortions.

The result is remarkably stable imaging performance with enhanced clarity and precision across all your applications.

Enhanced Dampening Capabilities

The revolutionary concept of composite layering elevates vibration control to unprecedented levels in imaging applications. By strategically combining materials with different damping properties, you’ll achieve superior isolation across multiple frequency ranges simultaneously.

When you pair viscoelastic compounds like Sorbothane with rigid structural layers, you create a system that efficiently captures and dissipates vibration noise that would otherwise compromise image quality.

This multi-material approach produces a synergistic effect where the whole truly exceeds the sum of its parts. You’ll notice dramatic improvements in imaging clarity as these advanced systems target specific vibration challenges through their varied densities and mechanical properties.

The layered configuration effectively intercepts disturbances from external sources, protecting your sensitive equipment and ensuring data integrity throughout the imaging process.

Customizing Dampening Solutions for Different Camera Types

As photographers and videographers push the boundaries of image quality, they quickly discover that different camera systems require uniquely tailored vibration dampening solutions.

Sorbothane mounts can be customized for your specific camera type, ensuring effective vibration isolation that protects both image quality and electronic components.

Your camera’s weight and exposure to various vibration frequencies determine the ideal damping thickness and shape needed.

For example, high-precision scientific cameras benefit greatly from Sorbothane anti-vibration blankets when capturing at extreme magnifications.

- DSLRs require different dampening than lighter mirrorless models

- Video cameras need solutions that address continuous operation vibrations

- Custom solutions can incorporate protection for attached accessories like lenses and stabilizers

Frequency-Specific Dampening Materials for Precision Imaging

When capturing images that demand exceptional clarity, selecting dampening materials that target specific vibration frequencies becomes essential to your success. Sorbothane leads the market by effectively absorbing vibration energy and dissipating it as heat, dramatically enhancing your image quality.

For best results, you’ll need frequency-specific damping solutions that address your particular imaging environment:

| Material/System | Effective Range | Isolation Efficiency |

|---|---|---|

| Sorbothane | Mid-range frequencies | High heat dissipation |

| Active Isolation Systems | As low as 0.7 Hz | Excellent for precision work |

| Negative-Stiffness Systems | 2 Hz and above | 93% at 2 Hz |

| Elastomeric Combinations | Wide frequency range | Enhanced performance |

Impact of Material Thickness on Vibration Absorption

Material thickness plays a vital role in determining vibration absorption efficiency, since thicker dampening materials generally capture and dissipate lower frequency vibrations more effectively.

When selecting dampening solutions for your imaging equipment, understanding thickness requirements can dramatically improve results—studies show properly sized elastomeric materials can reduce vibration amplitude by up to 99%.

- Thicker materials offer improved damping coefficients, essential for microscopy and other sensitive imaging applications where even minor vibrations can blur results.

- Application-specific thickness matters—heavier equipment often requires thicker dampening layers than lighter instruments.

- Balance thickness and weight carefully—excessive thickness adds bulk that may compromise your imaging setup’s stability.

Remember that ideal thickness varies by application, so you’ll need to match material properties to your specific vibration isolation needs.

Microscope-Specific Dampening Solutions for High Magnification

When setting up your high-magnification microscope, you’ll need to choose between active electronic dampening systems that continuously adjust to cancel vibrations and passive elastomeric mounts that absorb them without power requirements.

You can enhance isolation performance by combining layered materials with different density properties, creating a multi-stage dampening effect that targets various vibration frequencies.

Your selection should account for your specific imaging requirements, environmental factors, and budget constraints while ensuring the dampening solution can support your microscope’s full weight and accessories.

Active vs. Passive Systems

Although both active and passive vibration dampening systems serve essential roles in microscopy, their effectiveness varies considerably at high magnification levels where even nanometer-scale movements can compromise image quality.

When selecting between these options for your imaging setup, understanding their fundamental differences is vital.

Active vibration isolation systems excel at targeting low-frequency disturbances that passive solutions simply can’t address. These systems use electronic sensors and actuators to continuously monitor and neutralize vibrations in real-time.

- Negative-stiffness systems achieve up to 99.7% isolation at 10Hz, ideal for precision microscopy.

- Air-based tables may actually amplify vibrations in the 1.5-3Hz range.

- Passive elastomeric mounts provide basic dampening but fail with extreme low-frequency vibrations.

You’ll need to weigh setup complexity against imaging requirements when making your choice.

Layered Material Effectiveness

For microscopes operating at high magnification levels, layered dampening materials provide critical vibration isolation that can mean the difference between blurred images and crystal-clear results.

Products like Sorbothane effectively absorb low-frequency vibrations that would otherwise distort your imaging data.

You’ll achieve the best results by combining these layered materials with heavy granite bases, which act as passive isolators to reduce vibration amplitude.

For specialized applications, consider elastomeric mounts integrated within anti-vibration tables—they’re specifically designed to stabilize microscope platforms.

Don’t overlook the potential of active-air workstations when absolute precision is required. These systems electronically cancel vibrations that even the best passive materials can’t eliminate.

Remember to regularly assess your dampening system, as layered materials degrade over time, potentially compromising your imaging clarity.

Environmental Factors Affecting Dampening Material Selection

Because imaging equipment requires precise stability, environmental conditions play a critical role in selecting appropriate vibration dampening materials. Your vibration isolation system’s performance will vary considerably depending on temperature and humidity, which directly impact viscoelastic materials like Sorbothane.

Consider these critical environmental factors:

- Vibration sources – Heavy machinery or foot traffic introduce low-frequency vibrations requiring robust isolation solutions.

- Frequency and amplitude – Higher-amplitude vibrations demand materials with superior energy absorption capabilities.

- Load requirements – Heavier imaging equipment needs dampening materials that can support weight while maintaining isolation properties.

Temperature fluctuations will affect your dampening material’s performance over time, so select materials that maintain consistent properties under your specific laboratory conditions.

Always verify compatibility with your existing setup before implementing new dampening solutions.

Real-World Testing Methods for Vibration Reduction Materials

When evaluating vibration dampening materials for imaging applications, you’ll need reliable testing methods that replicate actual conditions rather than just theoretical specifications.

Seismic accelerometers provide precise measurement of vibration magnitude and frequency before and after applying damping materials.

You can conduct comparative analysis by placing accelerometers on various surfaces like floors and granite slabs. This reveals your measurement system’s ability to isolate sensitive equipment from external disturbances.

Simulate typical vibration sources—machinery operation or foot traffic—to assess how materials like Sorbothane perform in real scenarios.

Testing in controlled environments establishes a baseline for understanding performance during actual operational disturbances.

The collected data will show distinctive spikes corresponding to vibration events, helping you evaluate each material’s effectiveness at absorption and dissipation of unwanted energy.

Cost-Effective DIY Dampening Solutions for Camera Equipment

Three affordable DIY approaches can dramatically improve your imaging results without breaking the bank. You can transform ordinary materials into effective vibration dampeners with minimal investment, extending the life of your equipment while enhancing image quality.

- Place rubber mats or foam pads under your camera setup to immediately reduce vibration transfer from surrounding surfaces.

- Create custom anti-vibration mounts using Sorbothane sheets that absorb and dissipate unwanted movement energy.

- Add weight to your tripod with sandbags to increase stability against external disturbances.

For advanced cost-effective solutions, consider building a layered platform using plywood and rubber that isolates your entire setup from floor vibrations.

Remember to regularly inspect and replace worn materials in your DIY solutions to maintain their vibration-dampening effectiveness.

The Future of Nanomaterials in Vibration Control for Imaging

While DIY solutions offer practical, accessible options for immediate vibration control, revolutionary nanomaterials now promise to transform imaging technology at its foundation.

Graphene and carbon nanotubes deliver exceptional mechanical properties that dissipate vibrational energy far more effectively than traditional materials.

You’ll find these nanomaterials particularly valuable because their lightweight, flexible structure enhances equipment portability while maintaining superior performance.

Research shows nanomaterial composites can reduce vibration amplitude by up to 50%, remarkably outperforming conventional options like rubber or Sorbothane.

The high surface area-to-volume ratio of nanomaterials creates unprecedented interaction with vibrational energy, resulting in superior dampening.

Looking ahead, smart nanomaterials in development will likely adapt to changing frequencies in real-time, providing dynamic vibration control that optimizes your imaging quality across varied environments.

Frequently Asked Questions

What Is the Best Material for Vibration Dampening?

Sorbothane is your best choice for vibration dampening. It’s superior because it absorbs and dissipates energy as heat while returning to its original shape. You’ll appreciate its customizable thickness and exceptional performance.

Which Material Has the Best Damping Properties?

For damping properties, Sorbothane stands out as your best option. It’s uniquely effective at absorbing and converting vibration energy into heat, offering superior performance compared to traditional rubber, neoprene, or silicone materials.

What Is the Best Thing to Absorb Vibrations?

For absorbing vibrations, Sorbothane® is your best option. You’ll find its viscoelastic properties uniquely allow it to flow like liquid under impact, then return to shape while converting vibration energy into heat.

What Is the Best Damping Material?

For damping material, Sorbothane® stands out as your best choice. It’s uniquely viscoelastic, absorbing vibrations and dissipating energy as heat. You’ll appreciate its ability to flow under impact while maintaining its original shape.

In Summary

When choosing vibration dampening materials for your imaging setup, you’ll find that Sorbothane offers superior performance for most applications, while multi-layered solutions provide extensive control. Consider your specific environment and equipment needs. Don’t overlook the importance of proper installation—even the best materials won’t work effectively if poorly applied. Test different options in your actual working conditions rather than relying solely on manufacturer claims.

Leave a Reply