Stage controllers command high prices in 2024 due to premium materials, precision engineering, and advanced features like wireless connectivity and AI-assisted positioning. You’ll pay more for specialized manufacturing processes that maintain nanometer tolerances and rigorous quality control. Supply chain disruptions and component scarcity further drive up costs. The difference between manual ($200-$1,000) and motorized ($1,500-$10,000) options reflects their engineering complexity and long-term value. Discover why professionals consider these investments justified.

Numeric List of Second-Level Headings

Five essential topics frame our discussion of stage controller pricing in 2024. When you explore these key areas, you’ll gain a thorough understanding of why these professional tools remain premium-priced while their popularity keeps going strong.

- Premium Materials and Component Quality

- Advanced Feature Integration and Connectivity

- Specialized Manufacturing Processes

- Brand Value and Industry Reputation

- Technical Innovation and Customization Options

Each heading addresses a critical factor driving the cost of today’s stage controllers. From the durability requirements that demand high-grade materials to the labor-intensive assembly procedures that guarantee reliability, these elements combine to create instruments that command significant investment.

You’ll discover how manufacturer expertise and technological advancements continue to shape pricing structures throughout the professional audio equipment market, especially as musicians demand increasingly sophisticated performance tools.

The Evolution of Precision in Microscope Stage Controllers

You’ll notice dramatic improvements in stage controller precision since their inception, evolving from basic manual controls to today’s systems with nanometer-level accuracy.

Modern controllers now integrate closed-loop feedback systems and advanced stepper motors that enable movements as precise as 10-100 nanometers.

This precision revolution continues with emerging technologies that combine AI-assisted positioning and vibration compensation, allowing you to perform increasingly complex imaging tasks that were impossible just a decade ago.

Precision Evolution Timeline

When researchers first began using microscopy for detailed cellular observation, they relied on manual stage controllers that demanded steady hands and patience, often yielding inconsistent results.

The precision evolution timeline shows remarkable advancement throughout the decades. By the late 20th century, motorized stages emerged, offering improved control and repeatability in specimen positioning.

The early 2000s marked a pivotal shift with closed-loop control systems providing real-time feedback, enabling micrometer-level accuracy.

Today’s controllers incorporate high-resolution encoders and sophisticated algorithms that achieve sub-micron precision. You’ll find that modern digital interfaces allow you to program complex movements and automate imaging sequences, dramatically enhancing your research efficiency.

This technological progression explains why today’s high-precision stage controllers command premium prices—they’re delivering unprecedented accuracy that was unimaginable just decades ago.

Nanometer Control Advancements

The remarkable leap from micrometer to nanometer precision represents a quantum shift in microscope stage control technology. You’re now experiencing control resolutions as fine as 1 nanometer, transforming your research capabilities and image accuracy.

These nanometer control advancements stem from cutting-edge innovations in multiple domains:

| Component | Advancement | Benefit |

|---|---|---|

| Piezoelectric actuators | Rapid positioning | Enhanced responsiveness |

| Closed-loop feedback | Real-time monitoring | Drift compensation |

| Control algorithms | Complex automation | Simplified operation |

The integration of lightweight composites and precision manufacturing techniques further enhances these controllers’ durability while maintaining exquisite accuracy. When you’re working with nanometer-level precision, you’re leveraging sophisticated systems that continuously adjust positioning through feedback mechanisms, explaining why today’s stage controllers command premium prices despite becoming more cost-effective to manufacture.

Advanced Positioning Technology and Price Implications

Despite their substantial cost, advanced positioning technologies in modern stage controllers deliver precision that justifies their premium price tags. When you invest in these controllers, you’re paying for precision sensors and real-time tracking systems that require complex engineering and design processes.

The sophisticated positioning technology doesn’t come cheap—manufacturers must use high-quality materials and robust construction to guarantee your controller withstands rigorous touring conditions.

You’ll notice features like wireless connectivity and multi-channel integration that further drive up production costs.

Behind the scenes, cutting-edge software and firmware development requires ongoing investment, contributing considerably to the final price.

While the cost might seem steep, professional performers understand that reliable performance in live settings demands this advanced positioning technology—making it a necessary investment rather than an optional luxury.

Components That Drive Up Costs in Modern Stage Controllers

Breaking down a stage controller reveals why these precision tools command considerable price tags in 2024.

When you examine these devices, you’ll find they’re built with premium components rather than cheaper alternatives that would compromise performance.

High-quality mechanical switches and robust circuit boards form the foundation of reliable operation, while specialized low-latency processors guarantee your commands translate instantly to the stage.

The backbone of stage control lies in precision engineering—switches that never fail, circuits that endure, and processors that respond at the speed of performance.

You’re also paying for durable metal casings and high-grade plastics designed to withstand the rigors of touring.

The integration of advanced features like customizable profiles, touch-sensitive controls, and wireless connectivity through Bluetooth MIDI doesn’t come cheap.

These components greatly increase manufacturing complexity while delivering the professional-grade performance you need.

The expense directly reflects the superior materials and engineering required for dependable stage performance.

Research-Grade vs. Consumer-Level Stage Positioning Systems

Research-grade stage positioning systems command premium prices due to their sub-micron precision and near-zero drift rates you’ll need for critical applications.

You’re paying for manufacturing processes that maintain tolerances measured in nanometers, with quality control steps that reject components consumer systems would readily accept.

While consumer-level systems prioritize affordability through simpler designs and materials, you’ll notice they can’t deliver the stability required for sensitive research applications where even minor positioning errors compromise results.

Precision Differences Matter

When evaluating stage controllers in 2024, the precision differences between research-grade and consumer-level positioning systems greatly impact both performance and price.

You’ll find research-grade systems employ high-precision encoders and laser-based tracking technologies that consumer models simply don’t match.

These precision differences matter particularly in applications requiring exceptional accuracy. Research-grade controllers incorporate sophisticated calibration and error correction features absent in consumer alternatives, delivering superior reliability in demanding environments.

The integration of real-time data processing capabilities guarantees responsive performance that justifies the premium cost.

While consumer systems use basic sensors and materials to keep prices accessible, research-grade equipment undergoes rigorous testing to meet strict industry standards.

This fundamental quality gap explains why professional positioning systems command considerably higher prices despite serving similar basic functions.

Manufacturing Tolerance Requirements

The staggering difference between research-grade and consumer-level stage positioning systems becomes immediately apparent in their manufacturing tolerance requirements.

When you’re purchasing research-grade equipment, you’re paying for precision that’s often measured within ±0.1 mm tolerances—ten times tighter than the ±1 mm typically accepted in consumer systems.

These exacting manufacturing tolerances aren’t merely technical specifications; they’re fundamental to ensuring your stage controller delivers repeatable, reliable performance in demanding research environments.

The stringent requirements drive up production costs considerably as manufacturers must implement more sophisticated quality control processes and often discard components that don’t meet specifications.

While these tight tolerances contribute to the higher price tag, they directly translate to the longer lifespan and superior performance you’ll experience with research-grade systems compared to their consumer counterparts.

Stability Versus Affordability

Closely related to manufacturing tolerances is the fundamental tradeoff between stability and affordability in stage positioning systems.

When you’re investing in a stage controller, you’re fundamentally paying for reliability and performance consistency that cheaper alternatives simply can’t deliver.

Research-grade systems incorporate advanced engineering and premium materials that dramatically enhance stability—a critical feature for professional applications.

While consumer-level controllers offer basic functionality at attractive price points, they typically lack the durability needed for extensive professional use.

The stability features found in high-end controllers—robust weight distribution, precision components, and rigorous quality control—aren’t just luxury add-ons; they’re crucial for maintaining performance integrity.

What you’re really paying for is the assurance that your equipment won’t fail during critical moments, a value proposition that justifies the significant price difference between professional and consumer-grade options.

The Impact of Manufacturing Precision on Controller Pricing

Manufacturing precision stands at the core of why stage controllers command premium prices in 2024. When you purchase a professional controller, you’re paying for exacting tolerances that far exceed consumer-grade equipment standards.

This precision isn’t achieved easily—it requires skilled technicians performing meticulous hand assembly, greatly raising labor costs.

The components inside your controller further drive up pricing. High-quality switches, robust casings, and advanced materials comprise a substantial bill of materials.

Premium components command premium prices—high-grade switches, metal casings, and specialized materials aren’t manufacturing afterthoughts but performance necessities.

Additionally, manufacturers must incorporate design elements that guarantee compliance with strict safety regulations and electrical standards.

The sophisticated engineering behind features like multi-channel outputs and real-time performance capabilities adds another layer of expense.

These complex designs require extensive development and testing, ultimately reflected in the price you’ll pay for reliable, precision-engineered stage controllers.

Customization Options and Their Effect on Price Points

You’ll find that stage controllers command higher prices when they offer extensive customization options like programmable buttons, touch-sensitive pads, and compatibility with multiple DAWs.

Premium personalization extends to aesthetic choices, where you’re paying extra for custom colors, finishes, and specialized materials that enhance both form and function.

These tailored experiences aren’t just cosmetic—they’re backed by proprietary software systems that require ongoing development, pushing price points upward while delivering the personalized control experience that professional performers demand.

Premium Personalization Features

While basic controllers serve fundamental needs, the personalization features in today’s premium stage controllers contribute considerably to their elevated price points. When you invest in a high-end controller, you’re paying for the ability to make the device uniquely yours.

Premium personalization features now extend beyond simple functionality to include:

- Programmable elements including customizable pads, knobs, and faders that adapt to your specific workflow.

- Advanced MIDI mapping capabilities that allow you to tailor every control to your exact specifications.

- Aesthetic customizations such as RGB lighting, interchangeable caps, and custom skins that match your performance style.

These features require sophisticated software development and higher-quality components, driving costs upward.

However, for performers seeking gear that reflects their individual style, these premium personalization options justify the investment.

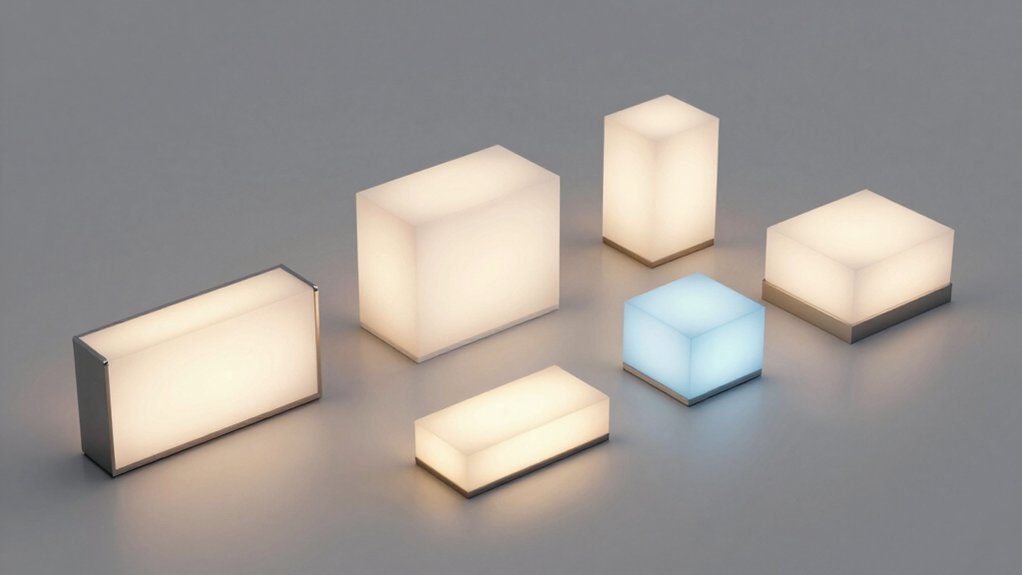

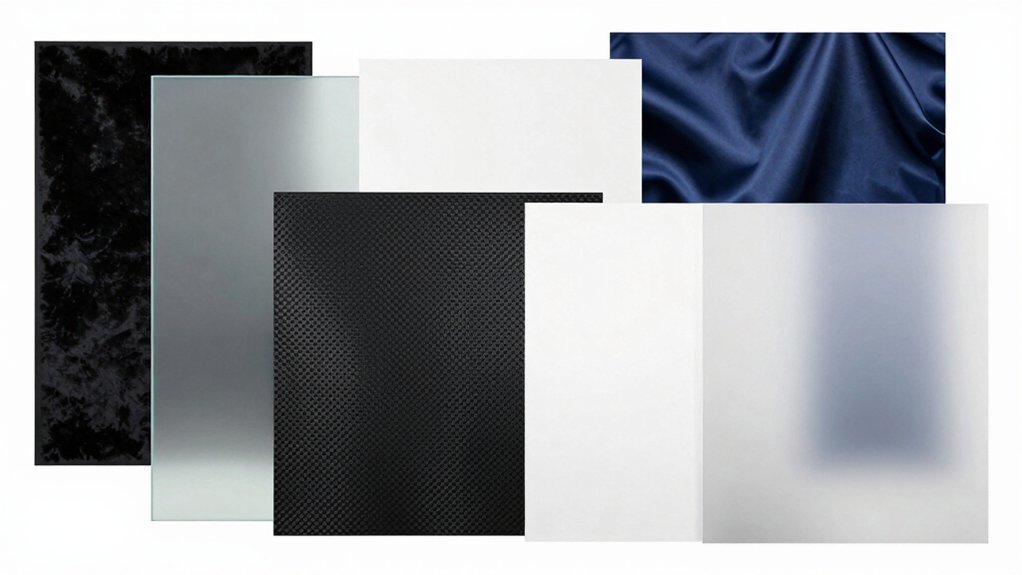

Material Selection Upcharges

Beyond basic functionality and software features, material choices greatly influence the final price tag of today’s stage controllers. When you opt for premium materials like aircraft-grade aluminum, hardwood casings, or specialized finishes, you’re paying for both aesthetic appeal and enhanced durability.

Material selection upcharges reflect the manufacturer’s increased costs for sourcing these premium components. Custom color options, textured surfaces, and eco-friendly materials all contribute to higher production expenses that get passed along to you.

Manufacturers are increasingly incorporating innovative materials like lightweight alloys that improve portability without sacrificing durability. These specialized engineering solutions require unique production methods that further elevate costs.

While these premium material choices greatly impact your wallet, they typically deliver superior performance, longevity, and stage presence that standard controllers simply can’t match.

Supply Chain Challenges Affecting Microscope Accessories

As global supply networks continue to buckle in 2024, microscope accessories have become casualties of widespread disruption.

You’re likely noticing the impact when purchasing stage controllers and other precision components. These supply chain challenges have particularly affected Temperature Control modules, as they require specialized materials now facing critical shortages.

The ripple effects appear in three primary ways:

- Component scarcity – Essential parts needed for manufacturing are increasingly difficult to source.

- Raw material inflation – Glass and plastics used in microscopy accessories have seen dramatic price increases.

- Logistics bottlenecks – Extended shipping times have created inventory gaps, forcing distributors to raise prices.

While manufacturers scramble to adapt, you’re unfortunately bearing the cost of these unprecedented supply chain constraints.

The Return on Investment for High-End Stage Controllers

Although high-end stage controllers command premium prices in 2024, their long-term value often justifies the initial investment.

When you purchase a professional-grade controller, you’re investing in durable construction and quality materials that will last a long time, withstanding the rigors of regular performances.

You’ll benefit from advanced features like customizable controls and extensive connectivity options that enhance your creative potential and workflow efficiency.

The reliability testing these controllers undergo means fewer technical failures during live shows, protecting your professional reputation.

Consider also that premium controllers retain higher resale value due to their build quality and reputation.

This means you can recoup a significant portion of your investment when it’s time to upgrade your gear, making the total cost of ownership more reasonable than the price tag suggests.

Comparing Manual vs. Motorized Stage Control Costs

When comparing stage controller options in 2024, you’ll notice a substantial price gap between manual and motorized systems.

Manual controllers typically cost between $200-$1,000, while motorized options start at $1,500 and can exceed $10,000 depending on capabilities.

This price difference stems from several factors:

- Engineering complexity – Motorized controllers require precision components, sophisticated electronics, and safety features that aren’t necessary in manual systems.

- Software integration – Advanced automation software bundled with motorized controllers adds significant value but increases overall cost.

- Assembly requirements – Motorized systems demand skilled technicians for assembly and calibration, driving up labor costs.

Professional users often justify the higher investment in motorized controllers because the precision, automation, and reliability deliver greater efficiency and capabilities that manual controllers simply can’t match.

Frequently Asked Questions

Why Is the PS5 Controller Expensive?

Your PS5 controller’s price reflects its advanced features like haptic feedback and adaptive triggers, premium materials, complex engineering, and high manufacturing costs. These technologies greatly enhance your gaming experience over previous controllers.

Is a Scuf Controller Better Than a Regular Controller?

Scuf controllers offer you customizable features like paddles and adjustable thumbsticks that regular controllers don’t have. They’re better if you’re competitive or want personalization, but you’ll pay more for these premium advantages.

How Much Does It Cost Sony to Make a Controller?

Sony’s manufacturing cost for a PlayStation controller is estimated between $18-30 per unit. You’re paying for advanced haptic feedback, adaptive triggers, high-quality materials, and R&D expenses when you purchase one.

Why Are Wired Controllers so Much Cheaper?

You’ll find wired controllers cheaper because they’re simpler to manufacture, lack wireless components and batteries, use standard parts, benefit from mass production, and don’t require advanced features found in elite models.

In Summary

You’ll see that premium stage controllers reflect their precision engineering, advanced materials, and specialized components. They’re investments that deliver accuracy and reproducibility for critical applications. While seemingly expensive in 2024, when you consider their reliability, automation capabilities, and long-term value, you’re actually paying for performance that directly impacts research outcomes and productivity. For many professionals, the benefits ultimately justify the cost.

Leave a Reply