To fix sensor cooling system problems, you’ll want to replace faulty temperature sensors, check coolant flow paths for blockages, clean ventilation paths and radiator fins, resolve electrical connection issues, test sensor resistance with a multimeter, maintain proper coolant levels, and consider upgrading to high-performance components. Regular cleaning prevents corrosion and guarantees accurate readings. Don’t overlook hidden deposits or corroded connectors that affect performance—these simple maintenance steps can save you from costly overheating repairs down the road.

7 Best Fixes For Sensor Cooling System Problems

When your vehicle’s cooling system starts acting up, addressing sensor-related issues quickly can prevent major engine damage and costly repairs.

Regular inspection and cleaning of your Engine Coolant Temperature Sensor and its connections helps prevent corrosion that can lead to faulty readings.

Keep your coolant at proper levels and check for leaks regularly, as low fluid can cause inaccurate sensor readings and overheating.

Use an OBD-II scanner to identify trouble codes like P0115 or P0117, which often indicate ECT sensor problems.

If you need to replace a faulty sensor, be sure to clear diagnostic codes afterward to reset your ECU for proper operation.

Always follow manufacturer specifications when selecting coolant types and mixtures to maintain ideal cooling system performance.

Checking and Replacing Faulty Temperature Sensors

You’ll need to locate your engine coolant temperature sensor, typically found near the thermostat housing or on the engine block with an electrical connector attached.

Once located, use a digital multimeter set to ohms to test the sensor’s resistance values at different temperatures, confirming that resistance decreases as the engine warms up.

If your readings don’t match specifications or you’ve found DTCs like P0115 during scanning, it’s time to replace the sensor with the battery disconnected and proper torque applied.

Locating Sensor Positions

Finding your vehicle’s temperature sensors requires both knowledge and patience, as these critical components are often tucked away in hard-to-reach areas. The Engine Coolant Temperature (ECT) sensor is typically positioned near the thermostat housing or cylinder head, where it can accurately monitor cooling systems performance.

Before attempting to locate or replace any temperature sensors, always consult your vehicle’s manual for the exact positioning specific to your make and model. This step saves considerable time and prevents potential damage to surrounding components.

Once located, inspect the sensor’s electrical connections for signs of corrosion or damage. These connections often deteriorate over time, causing inaccurate readings.

Remember that proper sensor location knowledge isn’t just valuable for replacements—it’s essential for routine maintenance to guarantee your engine operates at ideal temperatures.

Testing With Multimeter

Three essential steps can determine whether your temperature sensor needs replacement.

First, disconnect the sensor’s electrical connector and set your multimeter to ohms for resistance testing. Your engine temperature sensor should display specific resistance values according to the manufacturer’s specifications.

Second, verify the sensor responds properly to temperature changes—resistance should decrease as temperature rises. If your readings fall considerably outside the expected range, you’ve found the culprit behind erratic temperature gauge readings.

Finally, inspect electrical connections for corrosion or damage that might mimic sensor failure.

After installing a new sensor, clear error codes with an OBD-II scanner and monitor coolant levels during operation to guarantee proper cooling system function. This testing process helps prevent serious issues like engine overheating and poor fuel efficiency.

Inspecting Coolant Flow and Circulation Pathways

While diagnosing sensor cooling system problems, proper inspection of coolant flow and circulation pathways remains critical to preventing potential engine damage.

Check all hoses and passages for blockages that could interrupt circulation, as restricted flow often leads to overheating issues.

Thorough inspection of hoses and passages prevents circulation blockages that commonly trigger dangerous overheating conditions.

Examine your water pump’s operation, as its failure directly impacts coolant circulation. A pressure tester can help identify leaks around connections and seals that might be compromising system integrity.

Don’t overlook your thermostat—a stuck valve will disrupt normal flow patterns regardless of sensor readings.

Perform a radiator flush regularly to remove sediment and debris that accumulate over time.

This maintenance step guarantees unobstructed pathways for coolant and improves heat dissipation, protecting both sensors and engine components from temperature-related failures.

Clearing Obstructions in Cooling System Components

Check your sensor cooling system’s ventilation paths regularly for signs of restriction that can lead to performance issues.

You’ll need to employ proper dust removal techniques, such as compressed air cleaning or vacuum extraction, to maintain ideal airflow through critical components.

Effective debris detection methods include visual inspection with a flashlight, pressure testing to identify flow restrictions, and monitoring temperature differentials that might indicate hidden blockages.

Ventilation Path Inspection

Maintaining a clear ventilation path is vital for your sensor cooling system to function properly. Regularly inspect the areas around your radiator and cooling fan for leaves, debris, and other obstructions that can restrict airflow.

Check the radiator grille and front air dams for damage or blockages that might impede proper ventilation.

Don’t forget to examine your cooling fins on both the radiator and condenser. Dirt buildup greatly reduces heat dissipation efficiency, causing your system to work harder and potentially overheat.

- Leaves caught between cooling fins creating mini-dams that block essential airflow

- Bent or damaged fins resembling a collapsed ventilation highway

- Dust-caked radiator surfaces that trap heat instead of releasing it

Also inspect hoses for kinks that restrict coolant flow, ensuring your entire ventilation system works effectively.

Dust Removal Techniques

Once you’ve completed your ventilation path inspection, it’s time to tackle the dust and debris that’s settled within your system components. Effective dust removal techniques are essential for maintaining ideal cooling performance in your sensor system.

| Component | Cleaning Method |

|---|---|

| Radiator fins | Compressed air blast to remove dust buildup |

| Coolant reservoir | Wipe clean and check for sediment |

| Radiator cap | Inspect and clean sealing surfaces |

| Cooling fans | Blow out dust with air compressor |

| System passages | Use cooling system flush for deep cleaning |

Use compressed air to clean radiator fins thoroughly, ensuring maximum airflow. Remove obstructions around the cooling system components to prevent overheating. For stubborn buildup, consider a professional cooling system flush that will clear sediment from hard-to-reach areas. Regular maintenance of your coolant reservoir and radiator cap will help maintain proper pressure and prevent cooling efficiency problems.

Debris Detection Methods

To effectively maintain your sensor cooling system, detecting debris early is essential before it causes component failure. Regularly inspect your radiator and coolant reservoir for visible sediment that could restrict coolant flow.

When you notice performance issues, use a pressure tester to identify potential blockages in hoses and connectors.

The ECT sensor area requires special attention, as accumulated grime can interfere with temperature readings, leading to cooling system malfunctions.

For thorough cleaning:

- Look for rust-colored particles floating in the coolant reservoir, indicating internal corrosion

- Hold a flashlight behind radiator fins to spot debris trapped between cooling channels

- Examine the coolant color—murky or cloudy liquid suggests suspended contaminants

Using radiator flush solution periodically helps dissolve hidden deposits that visual inspection might miss, ensuring ideal sensor function and cooling performance.

Resolving Electrical Connection Issues to Cooling Controls

When your vehicle’s cooling system starts acting up, faulty electrical connections are often the culprits behind inconsistent temperature readings and potential overheating problems.

Thoroughly inspect all electrical connectors for signs of corrosion, wear, or damage, as these issues can disrupt communication between the ECT sensor and your vehicle’s computer.

Check that all wiring is securely fastened and free from fraying. Use a multimeter to test the ECT sensor’s resistance against manufacturer specifications to identify potential faults.

Regular cleaning of connectors prevents moisture buildup that leads to corrosion.

If problems persist after these inspections, connect a diagnostic tool to check for stored trouble codes related to the cooling system.

This targeted approach helps you pinpoint electrical connection issues quickly, saving time and preventing more serious engine damage.

Calibrating Temperature Threshold Settings

Electrical fixes address only part of your cooling system’s performance. Proper calibration of your engine coolant temperature sensor thresholds guarantees the ECU receives accurate data, preventing overheating while maximizing fuel efficiency.

Always refer to manufacturer specifications when adjusting these settings to maintain peak engine performance.

- Imagine your engine running smoothly at the perfect temperature, with coolant flowing efficiently through precisely monitored channels.

- Picture yourself connecting an OBD-II scanner, watching real-time temperature readings stabilize as you fine-tune threshold settings.

- Visualize clearing error codes after calibration, your dashboard free of warning lights as the system operates within ideal parameters.

Regular calibration checks can identify discrepancies before they cause rough idling or stalling.

After adjustments, clear stored error codes with your OBD-II scanner to reset the system and activate your new settings.

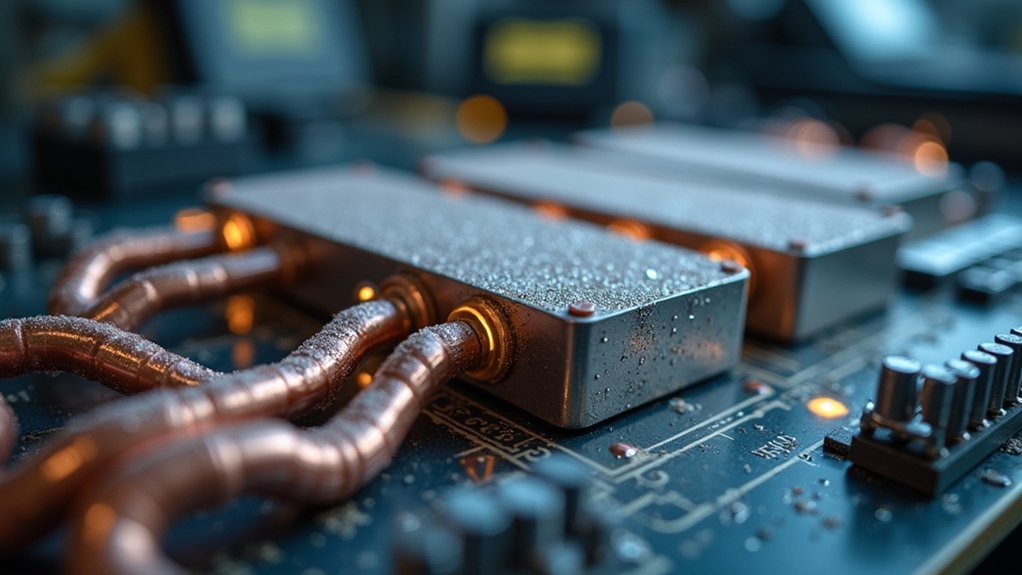

Upgrading Thermal Management Hardware

Upgrading your thermal management hardware delivers considerable improvements to cooling system reliability and performance, particularly in vehicles subjected to demanding conditions.

Installing high-performance ECT sensors enhances temperature reading accuracy, ensuring ideal coolant flow and improved engine efficiency.

Precise temperature monitoring through quality ECT sensors optimizes coolant circulation and maximizes engine performance.

Consider replacing your stock thermostat with an aftermarket model featuring a lower opening temperature to maintain cooler engine temperatures—especially beneficial for modified vehicles.

Electric cooling fans provide increased airflow during demanding driving conditions, while an upgraded radiator greatly improves heat dissipation and coolant circulation.

Don’t overlook the importance of high-quality coolant with superior heat transfer properties.

This simple upgrade enhances your cooling system’s effectiveness and extends the lifespan of your thermal management components, providing protection against overheating and costly repairs.

Frequently Asked Questions

How to Fix a Bad Coolant Temperature Sensor?

To fix a bad coolant temperature sensor, you’ll need to scan for error codes, check resistance with a multimeter, inspect connections, replace if necessary, and clear codes afterward to confirm the problem’s resolved.

What Can Cause a Coolant Temperature Sensor to Go Bad?

Your coolant temperature sensor can go bad due to extreme temperatures, corrosion, electrical issues, contamination from coolant leaks, or manufacturing defects. Regular maintenance helps catch these problems before they cause major engine issues.

What Happens if a Coolant Level Sensor Is Bad?

When your coolant level sensor fails, you’ll face inaccurate readings, potential engine overheating, erratic temperature gauge behavior, and warning light issues. You might experience decreased fuel efficiency and risk serious engine damage if problems go undetected.

How Do I Reset the Coolant Temperature Sensor?

To reset your coolant temperature sensor, disconnect your battery for 10-15 minutes, then reconnect it. Start your engine and let it reach normal temperature. Use an OBD-II scanner to clear any related diagnostic trouble codes.

In Summary

Don’t overlook the importance of regular maintenance for your sensor cooling systems. By implementing these seven fixes, you’ll extend equipment lifespan and prevent costly failures. Remember, most cooling issues stem from simple problems you can solve yourself. When in doubt, consult your system’s manual or call a professional. Proper sensor cooling maintenance isn’t just about repairs—it’s about protecting your valuable technology investment.

Leave a Reply