For successful scientific imaging, choose anti-vibration tables with Gimbal Piston isolators that dampen 10-100 Hz vibrations. Look for 304 stainless steel construction with load capacities up to 350 lb for your microscopes. Tables like SmartTable OTS (with IQ Damping) and Newport’s RS4000 reduce vibrations by up to 90%. Position your table on level surfaces away from machinery and HVAC systems. The right setup can dramatically improve your imaging clarity and experimental accuracy.

Understanding Vibration Sources in Scientific Imaging

When setting up your scientific imaging equipment, you’ll need to contend with vibrations that can derail even the most meticulously planned experiments. These disruptions come from multiple sources: foot traffic, machinery, and environmental factors like HVAC systems can all compromise your results.

Even subtle vibrations between 10-100 Hz—typical for building environments—can blur images and introduce data inaccuracies. Your lab may also experience resonance effects, where certain frequencies amplify vibrations dramatically.

Effective vibration management requires understanding your specific laboratory’s vibration profile. Different imaging techniques have varying sensitivity thresholds, meaning your anti-vibration tables must be matched to your particular needs.

Specialized vibration isolators are designed to dampen these frequencies, protecting your sensitive equipment and ensuring reliable, reproducible results.

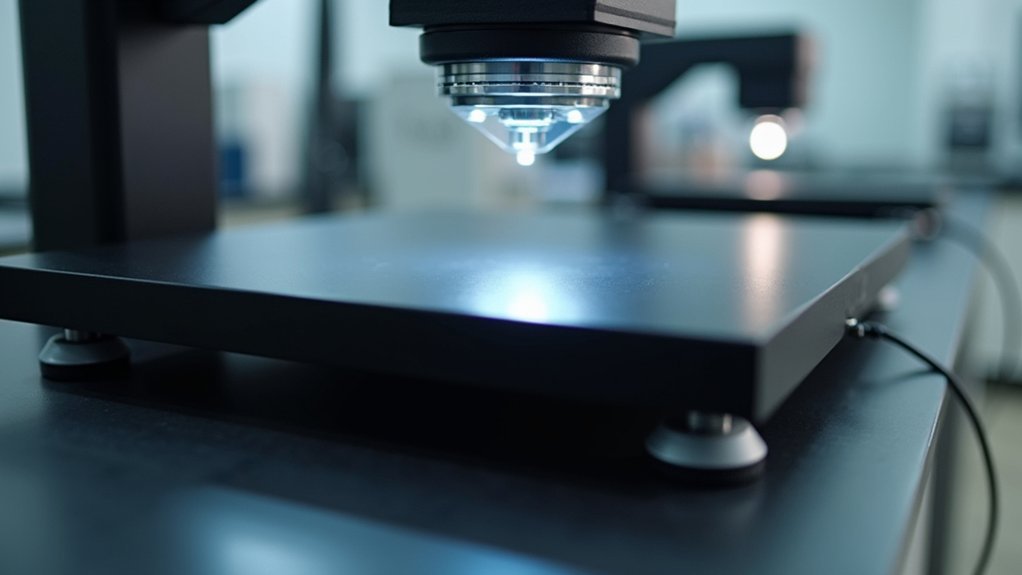

Key Features of Premium Anti-Vibration Tables for Microscopy

Premium anti-vibration tables represent the gold standard for microscopy applications where image clarity and data precision can’t be compromised. You’ll find these tables incorporate Passive Vibration Isolation technologies, achieving up to 90% reduction in typical building vibrations for exceptional microscopic imaging.

| Feature | Benefit |

|---|---|

| Gimbal Piston™ isolators | Dampens both horizontal and vertical vibrations |

| Load capacity (up to 350 lb) | Supports heavy microscopes and accessories |

| Telescoping height adjustment | Provides ergonomic customization |

| Vibration control systems | Guarantees stable imaging platform |

| 304 stainless steel construction | Cleanroom compatible and durable |

When selecting your microscopy table, you’ll want to take into account both the vibration control capabilities and load capacity needed for your specific applications.

Passive vs. Active Vibration Isolation Technologies

Passive isolation systems leverage mechanical designs with materials like rubber to absorb vibrations, while active pneumatic systems employ sensors and actuators that continuously counteract disruptive forces.

You’ll find that passive technologies offer cost-effective solutions with up to 90% vibration reduction, though active systems provide superior performance across a wider frequency range with real-time adjustments.

When selecting an anti-vibration table, you should evaluate whether your application’s sensitivity justifies the additional complexity and cost of active isolation or if a passive system will suffice for your specific requirements.

Mechanical vs. Pneumatic Designs

Choosing between mechanical and pneumatic anti-vibration tables represents one of the most critical decisions you’ll make when protecting sensitive equipment.

Mechanical designs use elastomeric mounts to absorb vibrations, offering a cost-effective passive solution for less demanding applications. Pneumatic designs, however, employ air-filled isolators with superior performance and lower natural frequencies (2-4 Hz).

When selecting between these options, consider:

- Application sensitivity – Pneumatic systems excel for high-precision environments where even minute vibrations matter.

- Budget constraints – Mechanical systems typically cost less while providing adequate protection for less sensitive instruments.

- Load capacity – Evaluate your equipment weight requirements against each system’s specifications.

Your choice ultimately depends on vibration sensitivity levels, specific application needs, and how much vibration isolation your scientific imaging equipment requires.

Vibration Control Principles

Understanding vibration control fundamentals requires distinguishing between two primary isolation technologies: passive and active systems.

Passive vibration isolation utilizes materials like rubber and foam to dampen vibrations cost-effectively. You’ll find these systems adequate for less demanding applications, offering broad frequency dampening without complex components.

In contrast, active vibration isolation employs sensors and real-time adjustments to counteract disturbances precisely. When you’re working with sensitive imaging equipment, these systems provide superior stability by dynamically responding to changing vibration conditions. They’re essential when external disturbances would otherwise compromise your results.

Your choice between these technologies should depend on your specific laboratory requirements, including load capacity and equipment sensitivity. For high-resolution scientific imaging, active systems typically offer the performance advantage worth their additional investment.

Performance Trade-off Analysis

When evaluating anti-vibration tables, you’ll need to weigh several key performance factors between passive and active isolation technologies.

Passive systems using rubber or foam provide cost-effective solutions with up to 90% vibration reduction, while active systems offer superior performance through real-time adjustments but at higher costs.

Consider these critical trade-offs:

- Frequency coverage – Passive isolation works well for common vibrations, but active technologies excel at adapting to varied disturbances.

- Budget vs. performance levels – Balance initial investment against the required effective vibration control for your sensitive instruments.

- Complexity vs. reliability – Simpler passive Anti-Vibration Tables require less maintenance, while active systems deliver enhanced stability for highly sensitive applications.

Your ultimate choice should align with your specific application sensitivity and environmental conditions.

Material Considerations for Optimal Performance

The success of an anti-vibration table largely depends on its material composition, as different materials exhibit varying abilities to isolate and dampen vibrations.

Material composition is the cornerstone of effective vibration isolation in laboratory and industrial tables.

When selecting your table, prioritize high-damping materials like rubber and specialized metals that excel at vibration isolation while supporting your required load capacity.

Honeycomb structures offer an impressive stiffness-to-mass ratio compared to granite, providing stability without excessive weight.

For side panels, composite wood delivers effective energy dissipation with structural integrity, whereas steel provides stiffness but may resonate more easily.

For precision applications, consider 304 stainless steel components for their durability and cleanliness benefits.

Remember that wider tables don’t automatically guarantee better performance—the geometry must be optimized for your specific environmental conditions to maximize vibration reduction.

Size and Load Capacity Selection Guide

Selecting the right size and load capacity for your anti-vibration table requires careful consideration of both your current and future equipment needs.

Tables typically support between 880-1200 lb, but you’ll need to account for proper weight distribution across isolators, which generally handle 25-100 lb each for ideal vibration isolation.

When choosing your table, focus on:

- Load requirements – Calculate total weight of all equipment and add 20% buffer for future additions

- Table dimensions – Consider the standard 1.25-inch height and whether it integrates with your existing workstation ergonomics

- Environmental factors – Assess nearby vibration sources like machinery or foot traffic that might affect isolation performance

Don’t overlook customization options for table sizes and load capacities that match your specific equipment and laboratory conditions.

Setting Up Your Anti-Vibration Table for Maximum Effectiveness

Setting up your anti-vibration table properly is essential for achieving peak performance with your sensitive equipment.

You’ll need to place the table on a level surface away from sources of vibration like HVAC systems or high-traffic areas.

Carefully follow the manufacturer’s leveling instructions, using a precision spirit level to guarantee perfect balance across all contact points of your table’s surface.

Proper Placement Essentials

When establishing your anti-vibration table, proper placement becomes essential for achieving ideal performance. Your isolation systems require thoughtful positioning to effectively combat unwanted vibrations.

Position your table on a solid, level surface away from high-traffic areas and operating machinery that generate disruptive vibrations.

For peak table system performance:

- Verify adequate airflow around the table to prevent equipment overheating and maintain proper functioning of active isolation components.

- Use the leveling adjustments (within ±0.25 inches/6mm) to compensate for minor floor irregularities.

- Regularly evaluate surrounding environmental conditions to confirm your anti-vibration table continues protecting sensitive instruments.

Surface Leveling Techniques

Proper placement lays the groundwork, but precise surface leveling truly determines your anti-vibration table’s performance. Always install your table on a level surface, using a quality leveling tool to verify horizontal and vertical alignment within ± 0.25 inches (6mm).

Don’t overlook the importance of balanced loads across your workspace. Uneven weight distribution can cause sagging that compromises your anti-vibration system’s effectiveness. Incorporate adjustable feet or pneumatic isolators to compensate for floor irregularities while maintaining ideal height.

Your table’s isolation capabilities will degrade over time if you neglect regular maintenance checks. Schedule periodic leveling assessments, as even minor settling can reduce vibration control.

These simple surface leveling techniques guarantee consistent performance, protecting your sensitive equipment and maintaining experimental precision long-term.

Real-World Performance Comparison of Leading Models

How do leading anti-vibration tables actually perform when put to the test?

When comparing actual performance, the SmartTable OTS with its IQ Damping Technology consistently outperforms competitors for live cell imaging, where vibration isolation tables support is critical.

Newport’s RS4000 Series delivers exceptional stability through its patented Gimbal Piston mechanisms that reduce vibrations by targeting specific resonance modes.

For your imaging needs, consider these performance differentiators:

- Hamilton Thorne tables reduce typical building vibrations by up to 90%, making them ideal for applications requiring microscopic precision.

- The Integrity VCS offers comparable stability to premium models at a lower price point.

- Electropolished stainless steel models provide both vibration control and cleanroom compatibility.

Frequently Asked Questions

How Long Do Typical Anti-Vibration Tables Last Before Requiring Replacement?

You’ll find most anti-vibration tables last 10-15 years with proper maintenance. They don’t typically “expire,” but may need replacement if damaged, if performance degrades, or when your precision requirements increase.

Can Anti-Vibration Tables Be Customized for Specific Imaging Applications?

Yes, you can customize anti-vibration tables for specific imaging applications. Manufacturers offer modifiable dimensions, weight capacities, damping properties, specialized surfaces, and accessory integration to meet your unique experimental requirements and equipment specifications.

Are Portable Anti-Vibration Solutions Effective for Fieldwork?

Portable anti-vibration solutions can be effective for fieldwork, but you’ll find they offer less stability than lab-grade tables. They’re a good compromise when you need mobility and adequate vibration control for less sensitive instruments.

How Do Temperature Fluctuations Affect Anti-Vibration Table Performance?

Temperature fluctuations can compromise your anti-vibration table’s performance by causing material expansion/contraction, altering dampening properties, and disrupting calibration. You’ll need temperature-stable environments for ideal vibration isolation in precision applications.

What Certifications Should I Look for When Purchasing an Anti-Vibration Table?

When purchasing an anti-vibration table, you’ll want to look for ISO certification, CE marking, ASTM compliance, and manufacturer-specific performance ratings that verify vibration isolation efficiency in your required frequency range.

In Summary

You’ll see dramatic improvements in your imaging results with the right anti-vibration table. Don’t overlook this vital equipment—match your choice to your specific vibration challenges, space constraints, and budget. Whether you select passive or active isolation technology, proper setup is essential. Your investment will pay dividends through sharper images, more reliable data, and extended equipment life in your lab.

Leave a Reply