Motorized microscope stages deliver superior imaging through nanometer-level precision, consistent positioning, and automated workflows that manual stages can’t match. You’ll benefit from enhanced reproducibility, reduced operator fatigue, and seamless software integration for complex imaging tasks. While manual stages offer tactile feedback and lower costs for basic applications, motorized options ultimately provide higher throughput and long-term value. The right choice depends on your specific imaging requirements and budget considerations.

Understanding the Core Differences Between Manual and Motorized Stages

When choosing between manual and motorized stages for microscopy applications, you’ll encounter fundamental differences that impact workflow efficiency and results.

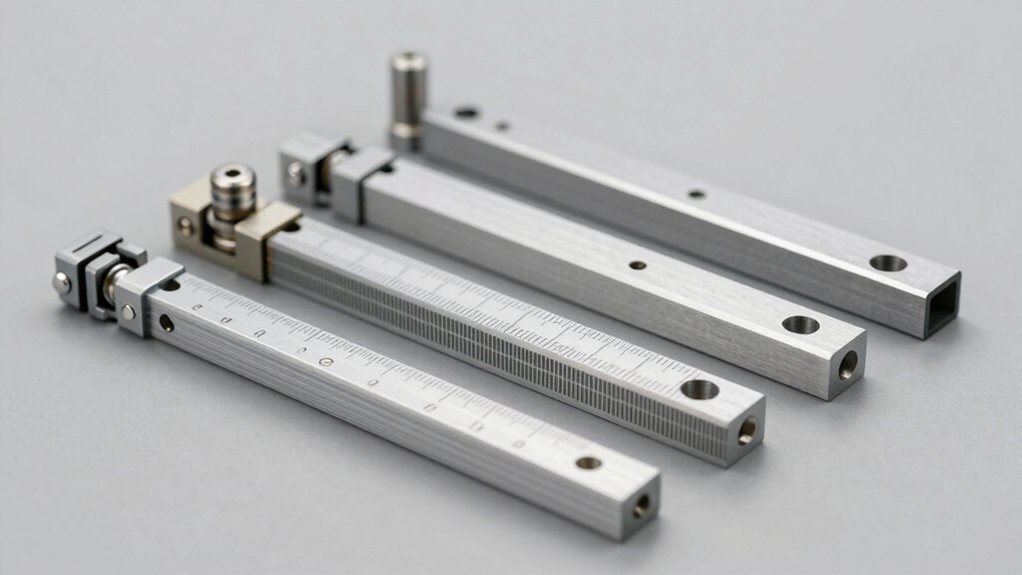

Manual stages require physical adjustments, introducing variability between operators, while precision motorized microscope systems offer electronic control with micrometer-level accuracy.

Motorized systems eliminate human variability, delivering consistent micrometer-precision that manual adjustments cannot achieve.

The high precision of motorized stages enables repeatable positioning that’s nearly impossible to achieve manually. You’ll benefit from automated multi-axis movements for complex imaging tasks, reducing the risk of sample contamination during delicate procedures.

Additionally, motorized stages allow you to store and recall specific positions—a significant advantage for reproducibility.

For long-term imaging applications requiring consistent performance, motorized stages like the U-780 deliver superior stability and rapid movement capabilities that manual alternatives simply can’t match.

Precision and Accuracy in Sample Positioning

Unlike manual systems, motorized stages deliver exceptional precision that transforms microscopy results.

Your imaging work benefits from positional stability up to 10 times greater thanks to self-locking ultrasonic motors in motorized microscope stages. This translates to accurate positioning with resolution capabilities down to 100 nanometers through integrated linear encoders.

When precision matters in your research, motorized microscope stages offer significant advantages:

- Micrometer-level control eliminates the variability inherent in manual adjustments

- Automated positioning routines let you store and recall specific sample locations

- Multi-axis synchronized movement enhances complex imaging tasks like image stitching

These capabilities guarantee consistently reproducible results while reducing contamination risks—critical factors when your work demands the highest level of precision and reliability.

Speed and Efficiency in Microscope Imaging Workflows

Although precision remains critical in microscopy, speed and efficiency often determine research productivity in demanding laboratory environments. With motorized XY stages moving up to 120 mm/second, you’ll position samples markedly faster than with manual systems.

| Feature | Manual Stages | Motorized Stages |

|---|---|---|

| Speed | Slow, operator-dependent | Up to 120 mm/second |

| Workflow | Sequential, manual | Automated, programmable |

| Return to Points | Not possible | Save and revisit locations instantly |

Automation enhances your efficiency through micrometer-level control and saved location points, allowing quick returns to specific inspection sites. This streamlines complex imaging tasks like image stitching, where multiple captures must align perfectly. The automated focus and positioning also guarantee consistent results across different operators, eliminating variability while increasing throughput for routine analyses.

User Experience and Ergonomic Considerations

Motorized stages greatly reduce your physical fatigue during extended imaging sessions, with joystick controls eliminating awkward reaching and repetitive hand movements.

You’ll notice a steeper initial learning curve with motorized systems, but this investment in time pays off through streamlined workflows and saved positions that eliminate redundant adjustments.

While manual stages offer immediate tactile feedback, motorized options ultimately provide you with a more comfortable, less physically demanding experience that can sustain productivity across hours of detailed inspection work.

Workflow Speed Analysis

When researchers evaluate microscopy systems, workflow speed emerges as a critical factor influencing both productivity and user satisfaction. Motorized stages deliver significant time-saving advantages over manual systems by automating complex movements with micrometer precision.

Your workflow can be dramatically accelerated through:

- Position memory functionality that allows quick changes between sample locations, eliminating repetitive manual adjustments

- Integrated automated imaging features that streamline data acquisition and analysis in optical systems

- Reduced physical interaction requirements that let you maintain focus on analysis rather than mechanical adjustments

The automation provided by motorized stages doesn’t just improve precision—it transforms your entire workflow efficiency.

Fatigue During Operation

Beyond workflow speed, the physical experience of operating microscopy equipment directly impacts research quality and sustainability.

When you’re spending hours at the microscope, manual stages can cause significant operator fatigue through repetitive physical adjustments and awkward positioning.

Motorized stages provide high levels of user comfort by eliminating these physical demands. You’ll control all movements via joystick or software, maintaining better posture throughout extended imaging sessions.

The ergonomic design of motorized systems also reduces eye strain, making your work more comfortable over long periods.

Research confirms these benefits aren’t just subjective—users of motorized setups consistently report lower levels of discomfort compared to manual stage operators.

This reduction in fatigue translates directly to improved productivity and job satisfaction, especially during complex imaging tasks requiring sustained concentration.

Learning Curve Comparison

Although both stage types serve similar functions, their learning curves differ dramatically for new users. When you’re operating a manual stage, you’ll need higher skill levels and greater familiarity with physical adjustments.

In contrast, motorized stages offer automation and intuitive interfaces that considerably reduce the learning curve.

The motorized advantage becomes evident through:

- Shorter training periods thanks to user-friendly software and automated features that streamline complex imaging processes

- Enhanced ergonomics with joystick controls and automated functions that prevent repetitive strain and awkward positioning

- Consistent imaging results across different operators due to automatic alignment and focus adjustments

You’ll also encounter fewer contamination risks with motorized options since they require less manual handling of microscope components—a critical benefit in sensitive research environments.

Cost Analysis: Initial Investment vs. Long-Term Value

Many laboratories face a critical decision when weighing the financial implications of manual versus motorized microscope stages. While manual stages offer a lower initial investment, making them attractive for budget-conscious labs, motorized options deliver substantial long-term value despite higher upfront costs.

Investing in motorized stages may strain initial budgets but yields significant operational advantages over time.

You’ll find motorized stages generate cost savings through increased efficiency and higher imaging throughput. Their superior reproducibility minimizes errors and reduces the need for repeated experiments, saving on materials and time.

Additionally, the modular design of motorized systems allows for gradual upgrades rather than complete replacements.

Don’t overlook the ergonomic benefits—motorized stages reduce physical strain on your team, potentially decreasing turnover and training costs.

When evaluating options, consider both immediate budget constraints and long-term operational value.

Image Stitching and Multi-Field Acquisition Capabilities

The technical advantages of motorized stages extend well beyond their financial benefits. When examining larger samples, you’ll find the automated image stitching capabilities invaluable for creating seamless thorough views. This technology transforms multiple images into unified data, enhancing your analytical capabilities.

Motorized stages deliver significant workflow improvements through:

- Streamlined multi-field acquisition that captures various sample locations efficiently

- The ability to save and return to specific coordinates, ensuring experimental reproducibility

- Faster shifts between fields of view, eliminating time spent on manual adjustments

The integration of motorized XY stages with advanced imaging software also produces more consistent results in image stitching.

If your work requires analyzing extensive sample areas or regular revisiting of specific locations, these capabilities represent substantial workflow advantages.

Repeatability and Reproducibility in Research Applications

When conducting research that requires accuracy across repeated tests, motorized stages outperform manual counterparts with their ability to return to exact positions with micrometer-level precision.

You’ll find that automated routines and position memory features eliminate human variability, ensuring your experimental protocols remain consistent regardless of the operator.

For long-term data consistency, the encoded positioning systems with 100 nanometer resolution in motorized stages provide the stability and reproducibility necessary for longitudinal studies and collaborative research projects.

Accuracy Across Repeated Tests

Scientific research demands consistency that manual stages simply can’t deliver reliably. When you’re conducting multiple tests over time, motorized microscope stages provide essential advantages through their capacity to store and precisely reproduce positioning settings with micrometer-level accuracy.

Your research benefits from motorized stages in several key ways:

- Elimination of human error that often plagues manual operations, considerably improving reproducibility of your findings

- Software integration enabling automated multi-point inspections that maintain identical parameters across experiments

- Seamless shifts between magnifications and focal planes, ensuring consistent imaging conditions for every test

These precision capabilities transform your research workflow, allowing you to focus on analysis rather than struggling with positioning variability that can compromise data integrity and experimental validity.

Long-term Data Consistency

Maintaining experimental integrity throughout lengthy research projects requires more than just initial precision—it demands consistent reproducibility that manual stages simply can’t deliver. When you’re tracking cellular changes over weeks or comparing multiple experimental runs, motorized stages guarantee your data remains reliable.

| Feature | Manual Stage | Motorized Stage |

|---|---|---|

| Location Memory | Limited by notes | Digital coordinates saved |

| Positioning Error | Increases over time | Remains constant |

| Multi-point Tracking | Difficult | Automated sequences |

| User-to-user Variance | High | Minimal |

Integration With Imaging Software Systems

Because motorized stages communicate directly with imaging software, they offer significant advantages over manual systems for complex microscopy applications.

You’ll find that these stages enable seamless automation for tasks like image stitching and data analysis, dramatically improving your workflow efficiency compared to manual alternatives.

When you use motorized stages with imaging software, you’ll benefit from:

- Automated Multiple Image Alignment (MIA) and Extended Focal Imaging (EFI) capabilities for thorough 3D analysis

- Precise control over observation methods with automatic configuration based on predefined conditions

- Enhanced communication through feedback mechanisms that improve accuracy in objective lens identification

These integration capabilities allow you to execute complex image analysis tasks quickly, delivering consistent results while reducing processing time—something simply not possible with manual stage manipulation.

Maintenance Requirements and Durability Factors

When comparing long-term reliability between stage types, you’ll find that manual and motorized options present distinctly different maintenance profiles.

Manual stages demand regular lubrication and mechanical adjustments to maintain performance, whereas motorized versions typically feature sealed components that reduce these hands-on requirements.

You’ll benefit from motorized stages’ high-stability motors that deliver consistent positional accuracy while minimizing wear over time. Their integrated linear encoders enable precise calibration, reducing mechanical stress and extending equipment lifespan.

Though both systems require regular inspections, motorized stages often include built-in diagnostics that alert you to maintenance needs before problems develop.

The durability of motorized options is further enhanced by their ability to perform repetitive tasks without the physical strain that eventually degrades manual mechanisms, ultimately resulting in fewer repairs and replacements.

Specialized Applications: When Manual Stages Excel

You’ll find manual stages particularly valuable in budget-constrained research settings where expensive motorized systems aren’t feasible.

They’re also ideal for simple inspection tasks where quick adjustments matter more than automated precision.

In limited space environments, manual stages offer a compact solution without the additional bulk of motors and controllers.

Budget-Friendly Research Applications

Despite the growing popularity of automated systems, manual stages remain indispensable in research settings with limited funding or basic operational requirements. When you’re managing a lab with budget constraints, these cost-effective solutions deliver impressive value without sacrificing essential functionality.

Manual stages offer several advantages for budget-conscious researchers:

- Micrometer-level precision that allows for intuitive, hands-on adjustments during experiments

- Noticeably lower maintenance and operational costs compared to motorized alternatives

- Straightforward operation that makes them ideal for educational environments and entry-level applications

For routine procedures like basic histology or cell culture inspections, you’ll find manual stages provide all the necessary capabilities without the expense of automation.

This makes them particularly well-suited for small labs, teaching facilities, and specialized applications where high-volume imaging isn’t required.

Simple Inspection Tasks

Beyond budgetary considerations, manual stages shine particularly in straightforward inspection scenarios where simplicity and tactile control matter most.

When you’re conducting basic microscopy observations, manual stages provide intuitive handling without complex setup requirements.

You’ll appreciate the tactile feedback that enables precise adjustments during careful observations—your fingers can feel minute movements that translate directly to sample positioning. This direct connection is invaluable when you need to quickly inspect different samples without recalibrating equipment.

Manual stages also prove more reliable in environments with electronic interference, ensuring consistent performance where motorized options might falter.

When your lab frequently switches between sample types, the flexibility of manual positioning eliminates the need for software adjustments or reprogramming, allowing you to adapt instantly to changing inspection requirements.

Limited Space Environments

Laboratories with spatial constraints often find manual stages to be the ideal solution. Their compact footprint allows integration into tight setups without the additional space required for motors and controllers.

You’ll appreciate the immediate tactile feedback when making precise adjustments in confined areas where electronic interfaces might be difficult to access.

The advantages of manual stages in space-limited environments include:

- Simplified maintenance with fewer failure points—critical when access for repairs is restricted

- Faster positioning capabilities without waiting for motorized movements

- Cost-effectiveness for labs with budget limitations but still requiring quality imaging results

This combination of space efficiency, direct control, and reliability makes manual stages particularly valuable when working with limited physical space while still needing accurate microscopy positioning.

Specialized Applications: When Motorized Stages Excel

While manual stages serve well for basic microscopy, motorized stages truly shine in specialized research applications where precision is non-negotiable.

You’ll benefit from micrometer-level control that enables highly accurate, repeatable positioning—critical for automated imaging and time-lapse studies.

The ability to store and recall specific positions streamlines your workflow in environments demanding reproducibility, such as 3D imaging and large-scale surveys.

When you need to stitch multiple images together, synchronized multi-axis movement delivers superior composite results.

You’ll also appreciate motorized stages in sterile environments where remote operation reduces contamination risk—perfect for biomedical research and material testing.

When integrated with advanced imaging software, you’ll reveal capabilities like automated point inspections and extended focal imaging, providing thorough data that manual stages simply can’t match.

Future-Proofing Your Microscopy Setup: Modular Upgrade Paths

Investing in microscopy equipment represents a significant commitment, but modular systems offer an intelligent pathway to protect that investment over time. The PA53MET exemplifies this approach, allowing you to begin with essential components and upgrade strategically as your needs evolve.

This modular philosophy provides several advantages:

- Start with a manual configuration and shift to motorized components when your workflow demands greater precision.

- Customize your setup for specific applications without replacing the entire system.

- Allocate your budget efficiently by prioritizing upgrades that deliver immediate value.

Frequently Asked Questions

Can Stages Be Retrofitted From Manual to Motorized Operation?

Yes, you can retrofit manual stages to motorized operation. Many manufacturers offer conversion kits that replace manual knobs with motors and controllers, allowing you to upgrade without replacing the entire stage system.

How Do Vibrations From Motorized Stages Affect Sensitive Samples?

Vibrations from motorized stages can damage delicate samples or blur images. You’ll need to select stages with low vibration profiles and consider isolation systems for extremely sensitive applications.

Do Manual Stages Offer Better Tactile Feedback for Pathology Workflows?

Yes, manual stages give you better tactile feedback for pathology workflows. You’ll feel subtle tissue resistances and can make precise adjustments intuitively, which helps when examining delicate specimens or steering through complex tissue architectures.

What Backup Options Exist if Motorized Control Systems Fail?

If your motorized control systems fail, you’ll find several backup options: manual override knobs, alternative control interfaces, emergency power supplies, temporary manual stages, and repair services while you troubleshoot the electronic components.

How Do Different Stage Types Perform in High-Humidity Environments?

In high-humidity environments, you’ll find motorized stages more vulnerable to corrosion and electrical failures. Manual stages perform better as they’re simpler with fewer sensitive components, though you should still use desiccants with either type.

In Summary

Your choice between manual and motorized stages depends on your specific imaging needs. If you’re budget-conscious and performing basic research, manual stages offer reliability with lower costs. For applications requiring precision, automation, or high-throughput imaging, motorized stages deliver superior results despite the higher investment. Consider your workflow, sample types, and future research direction before deciding which technology will serve your imaging goals best.

Leave a Reply