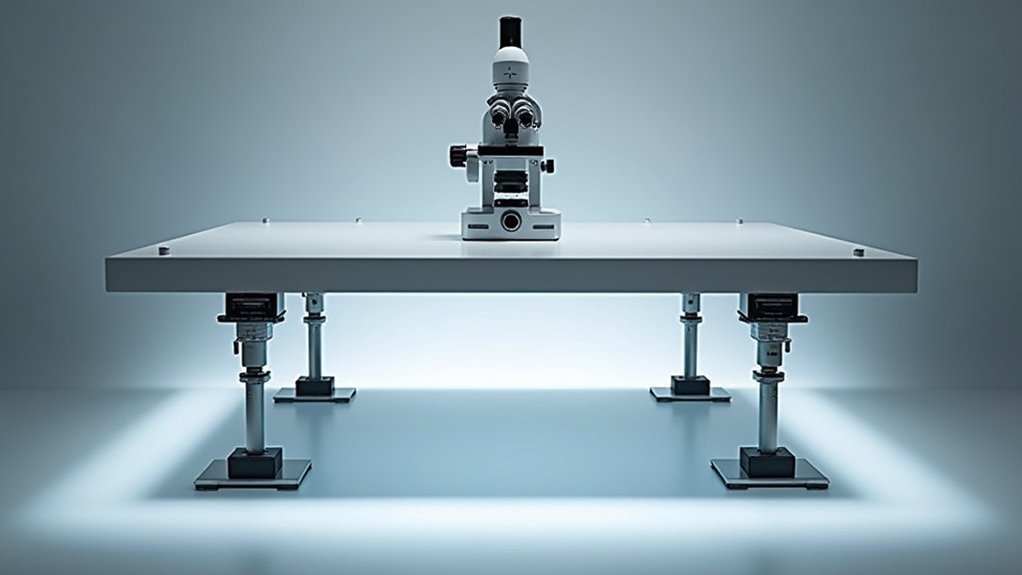

A vibration-free floating table setup isolates sensitive equipment like microscopes and cameras from environmental vibrations. You’ll find these specialized workstations use pneumatic or mechanical systems to dampen disturbances, typically reducing ambient vibrations by up to 90%. The best setups maintain natural frequencies below 4 Hz for peak performance. Materials like granite or stainless steel provide stability while viscoelastic polymers absorb remaining vibrations. Proper setup guarantees your precision instruments deliver their full potential without interference.

13 Second-Level Headings for “What Is A Vibration-Free Floating Table Setup?”

Each heading addresses essential elements of these sophisticated setups.

Under “Principles,” you’ll learn how pneumatic isolators reduce floor vibrations by up to 90%.

Pneumatic isolator systems effectively dampen environmental vibrations, preserving precision in sensitive research equipment.

“Components” covers the honeycomb structures and stainless steel construction that create an ideal stiffness-to-mass ratio.

“Performance Metrics” helps you evaluate effectiveness for your specific needs, while “Application-Specific Configurations” examines customization options like adjustable height features for laboratory and cleanroom environments.

These divisions guarantee you’ll grasp both fundamental concepts and practical considerations of vibration-free technology.

Core Principles of Vibration Isolation in Microscopy

While microscopy requires extraordinary precision, even minor vibrations can greatly compromise image quality and measurement accuracy. That’s why effective vibration isolation is critical for your microscopy work.

The core principle involves creating a passive dampening system that combines substantial mass with optimized support stiffness to counteract environmental vibrations.

You’ll find that quality setups can reduce ambient vibrations by up to 90% through pneumatic isolation mounts that achieve impressively low natural frequencies (2-4 Hz). These systems effectively disconnect your sensitive equipment from building vibrations caused by foot traffic and machinery.

Materials matter too—stainless steel and granite components provide both stability and cleanliness benefits.

When properly implemented, these vibration isolation principles guarantee your microscopy results remain reliable and clear, particularly for high-magnification applications like IVF procedures.

Types of Floating Table Systems for Microscopes

When selecting a vibration-free setup for your microscope, you’ll encounter three main systems: pneumatic isolation platforms that use air pressure to absorb vibrations, active vibration control systems that detect and counteract disturbances in real-time, and passive mechanical systems that rely on mass and stiffness to dampen unwanted movements.

Pneumatic systems excel in laboratory environments with significant environmental vibrations, while active control systems offer superior performance for ultra-sensitive applications despite their higher cost.

Passive mechanical systems, like the AVT tables with load capacities of 26-50kg, provide a reliable and maintenance-free solution that can achieve up to 90% reduction in typical building vibrations.

Pneumatic Isolation Platforms

Among the most effective vibration dampening solutions, pneumatic isolation platforms stand out by utilizing air-filled chambers that absorb vibrations before they reach sensitive microscope equipment. You’ll find these systems maintain a natural frequency below 2-4 Hz, effectively isolating your microscope from building vibrations and environmental disturbances.

| Feature | Benefit |

|---|---|

| Air-filled chambers | Absorb up to 90% of vibrations |

| Adjustable height | Accommodates various setup needs |

| Stainless steel construction | Guarantees durability and easy cleaning |

| Variable load capacity | Supports different equipment weights |

These pneumatic vibration systems can dramatically improve your measurement precision, making them essential for high-accuracy applications. With their customizable settings and robust construction, you’ll achieve the stability needed for the most demanding microscopy work.

Active Vibration Control

Unlike passive systems, active vibration control technologies represent the cutting edge of floating table solutions for microscopy.

These sophisticated systems continuously monitor and counteract unwanted movements in real-time, offering superior protection for your sensitive instruments.

When you integrate an active vibration isolator into your laboratory setup, you’ll experience:

- Up to 95% isolation efficiency from external disturbances

- Real-time algorithmic adjustments that adapt to changing conditions

- Customizable damping characteristics for your specific equipment needs

- Noticeably enhanced microscope performance for critical imaging tasks

- Best stability for live cell imaging and detailed material analysis

Active systems utilize sensors and actuators working together to create a responsive environment that maintains stability even under challenging conditions.

This technology guarantees your microscopy work remains precise and reliable regardless of environmental vibrations.

Passive Mechanical Systems

Passive mechanical systems represent the foundation of anti-vibration technology in laboratory settings. When you’re working with sensitive equipment like microscopes, these Anti-Vibration Tables provide remarkable stability by combining mass with carefully calibrated support stiffness. They’ll reduce typical building vibrations by up to 90%, maintaining a balanced one-to-one horizontal-to-vertical stillness ratio.

| Feature | Specification |

|---|---|

| Vibration Reduction | Up to 90% |

| Natural Frequency | 2-4 Hz |

| Standard Dimensions | 1200x800mm |

| Mount Load Capacity | 25-100 lb per mount |

| Maximum Net Load | 350 lb (159 kg) |

The pneumatic mounts in these systems operate at impressively low natural frequencies (2-4 Hz), effectively dampening external disturbances before they reach your equipment. This guarantees your experiments proceed with maximum precision, regardless of surrounding environmental factors.

Pneumatic vs. Mechanical Isolation Mechanisms

You’ll find pneumatic isolation systems operate using compressed air chambers that create a natural frequency of 2-4 Hz, while mechanical systems rely on springs and dampers to achieve similar vibration dampening.

When unexpected disturbances occur, pneumatic isolators automatically adjust to varying loads without manual intervention, offering superior performance across broader frequency ranges.

Though pneumatic systems provide better overall isolation, they’re typically more expensive and require air supply infrastructure, whereas mechanical options offer simpler maintenance and lower initial costs despite their performance limitations.

Operating Principles Compared

When selecting a vibration isolation system, understanding the fundamental differences between pneumatic and mechanical mechanisms becomes essential for best performance.

Pneumatic systems use air-filled cushions operating at 2-4 Hz natural frequency for superior vibration damping, while mechanical systems rely on springs and masses for passive isolation.

- Flexibility vs. Simplicity – Pneumatic systems offer adjustable performance but mechanical solutions require no air supply.

- Performance Trade-offs – Air cushions excel at low frequencies where sensitive measurements happen.

- Maintenance Considerations – Choose between regular pneumatic upkeep or maintenance-free mechanical options.

- Load Adaptability – Pneumatic systems can be reconfigured by adding weights.

- Environmental Resilience – Pneumatic isolation typically outperforms in changing ambient conditions.

You’ll need to balance these operating principles against your specific equipment needs and facility constraints.

Performance Under Disturbances

Despite facing similar environmental challenges, pneumatic and mechanical isolation systems respond dramatically differently when confronted with real-world disturbances.

When you’re dealing with vibrations, pneumatic isolators clearly outperform their mechanical counterparts, offering reduction of building vibrations by up to 90%. This impressive performance stems from their ability to achieve natural frequencies as low as 2-4 Hz, effectively neutralizing both high and low-frequency disturbances that mechanical systems often struggle to mitigate.

You’ll also appreciate how pneumatic systems adapt to varying loads without manual intervention, maintaining consistent performance regardless of weight changes.

Mechanical systems, relying on springs and dampers, typically require adjustments when load conditions change. If precision is critical for your application, pneumatic isolation provides superior stability and disturbance rejection across a wider spectrum of environmental conditions.

Cost-Benefit Analysis

Evaluating vibration isolation systems requires looking beyond performance metrics to understand their economic implications.

When comparing pneumatic and mechanical vibration control solutions, you’ll find pneumatic systems offer superior long-term value despite higher initial investments.

- Pneumatic isolators reduce building vibrations by an impressive 90%, protecting your sensitive equipment more effectively.

- Low natural frequency (2-4 Hz) of pneumatic mounts delivers exceptional performance where mechanical systems struggle.

- You’ll appreciate the adaptability of pneumatic systems as they adjust automatically within ±6mm to changing loads.

- Your maintenance costs practically disappear with pneumatic systems’ maintenance-free design.

- Installation time and complexity decrease markedly with pneumatic systems’ simpler setup requirements.

While mechanical systems may seem less expensive upfront, their ongoing maintenance requirements and reduced effectiveness make pneumatic isolation the more economical choice for sustained vibration control.

Selecting the Right Table Size and Weight Capacity

Choosing the appropriate dimensions and weight capacity stands as a critical first step in setting up your vibration-free floating table.

Consider whether the platform size—such as the 1200x800mm AVT table—will accommodate your equipment while fitting your workspace constraints.

You’ll need to match your equipment weight to the table’s spring system. Tables with 2 springs perform effectively with 26-32kg loads, while 3-spring models handle 32-50kg.

Overall weight limits typically range from 880-1200 lb, providing flexibility for various setups.

Don’t forget to factor in the table’s own weight (approximately 258 lbs) when calculating total load.

Finally, verify your selected model allows for leveling adjustments within ±6mm to compensate for uneven surfaces and maximize stability during operation.

Material Considerations for Maximum Stability

When selecting materials for your vibration-free floating table, you’ll need to weigh the superior thermal stability of granite against the lighter weight and customizable properties of composite materials.

The dampening layers between your table’s core and surface should feature viscoelastic polymers that convert kinetic energy into heat, effectively absorbing both high and low-frequency vibrations.

Your material choices must account for thermal expansion coefficients, as even minor temperature fluctuations can compromise precision measurements and affect experimental repeatability.

Granite Vs Composite Materials

Although both options enjoy widespread use in precision environments, granite and composite materials present distinct advantages for vibration-free floating tables.

When choosing between them, you’ll need to evaluate your specific requirements. Composite materials typically offer better vibration damping with a higher stiffness-to-mass ratio, while granite provides excellent stability with greater mass.

- Granite’s impressive weight creates natural isolation but limits mobility and flexibility.

- Composite structures allow for customized designs that traditional stone can’t match.

- The natural damping properties of composites prevent resonance that granite might experience.

- You’ll find greater versatility with composites for specialized applications.

- Your investment in either material directly impacts the performance of vibration-sensitive equipment.

Consider your space constraints, equipment sensitivity, and frequency requirements when making your selection.

Dampening Layer Properties

The right dampening layer serves as the cornerstone of any effective vibration-free floating table.

You’ll find that viscoelastic materials offer superior energy absorption across wide frequency ranges, effectively minimizing resonance issues that could affect your sensitive equipment.

When selecting your dampening layer, consider both thickness and composition. Softer materials work best for lower frequencies, while firmer options handle higher-frequency vibrations more effectively.

For maximum stability, pair your dampening layer with high-density materials like granite or heavy steel to increase mass and further reduce vibration transmission.

For specialized applications, you can incorporate advanced technologies such as tuned mass dampers.

These targeted solutions optimize vibration control precisely where you need it most, ensuring your floating table meets the exacting requirements of precision instruments and laboratory setups.

Thermal Stability Factors

Beyond effective dampening layers, thermal stability emerges as a defining factor in maintaining precision across your vibration-free floating table system. Your material choices directly impact thermal performance and measurement accuracy.

- 304 stainless steel and granite provide exceptional thermal stability with minimal expansion, protecting your most sensitive measurements.

- Honeycomb structures deliver remarkable stiffness-to-mass ratios, maintaining thermal stability without unnecessary weight.

- Properly insulated enclosures create uniform temperature environments, eliminating gradient-induced errors.

- Thicker table surfaces act as thermal buffers, absorbing and distributing temperature fluctuations for consistent performance.

- Mismatched thermal expansion coefficients create hidden stresses that compromise your setup’s integrity.

When designing your vibration-free system, prioritize thermal stability through compatible materials. The right composition prevents microscopic movements caused by thermal expansion and contraction, preserving your measurements’ integrity during extended operations.

Setting Up Your Floating Microscope Platform

Properly setting up your floating microscope platform involves four vital steps to guarantee ideal vibration isolation.

First, select a location away from high-traffic areas and equipment that generates vibrations. This placement is essential for your vibration-free floating table setup to function effectively.

Second, verify the table can support your microscope’s weight, staying within the 26-50 kg recommended capacity range.

Third, level the platform using the adjustable feet or stabilizers before placing your equipment.

Finally, test the anti-vibration mechanism by gently tapping nearby surfaces. Your microscope should remain stable, demonstrating that the stainless steel platform is properly absorbing external disturbances.

Tuning Dampening Systems for Optimal Performance

Once your floating table setup is in place, tuning the dampening systems becomes critical for achieving peak vibration isolation.

You’ll need to adjust mass, spring constants, and damping coefficients to match your specific equipment requirements.

- Feel the satisfaction when your tuned mass dampers eliminate those frustrating resonance peaks!

- Experience the confidence of selecting the perfect isolator rating between 25-100 lb for your setup.

- Enjoy the peace of mind that comes from seeing clean compliance and transmissibility curves.

- Marvel at how broadband damping techniques transform your workspace into a vibration-free zone.

- Celebrate the precision your equipment achieves when perfectly isolated from environmental vibrations.

For best results, combine multiple tuning methods to create an all-encompassing dampening system that addresses both narrow frequency problems and broadband vibration concerns.

Measuring and Evaluating Vibration Reduction

After implementing your floating table system, you’ll need reliable measurement techniques to verify its performance.

Effectiveness is typically assessed through compliance curves, which display the dynamic response of your table top to external vibrations, and transmissibility curves that reveal how well your isolators filter unwanted frequencies.

You can expect up to 90% vibration isolation with properly configured pneumatic or passive dampening systems.

For ideal evaluation, monitor the horizontal-to-vertical stillness ratio, aiming for the perfect one-to-one relationship that guarantees uniform stability in all directions.

Don’t overlook the importance of load adjustments within ±0.25 inches (6 mm) to fine-tune performance for your specific weight configuration.

Heavy materials like granite in your setup will further enhance measurement accuracy by attenuating both machinery-induced and seismic vibrations.

Environmental Factors Affecting Table Performance

Even the most meticulously designed floating table systems can be compromised by environmental variables that infiltrate your laboratory space. Your vibration-free tables are particularly susceptible to external forces that can undermine measurement accuracy despite sophisticated isolation techniques.

- Wind currents striking your building can transfer subtle vibrations through structural elements.

- Building mechanical systems create micro-movements that bypass standard isolation methods.

- Seismic activity, even minor tremors undetectable to humans, disrupts horizontal-to-vertical stability.

- Temperature fluctuations cause materials to expand and contract, affecting calibration precision.

- Humidity variations alter the performance characteristics of isolation components.

Understanding these environmental challenges helps you maintain peak performance of your vibration-free tables.

Remember that while mass elements like granite slabs provide resistance to local disturbances, environmental control remains essential for preserving the 90% vibration reduction capabilities of high-quality platforms.

Integrating Camera Equipment With Floating Tables

Three critical considerations must guide your approach when mounting camera equipment on vibration-free floating tables.

First, respect the recommended load capacity of 26-50kg to maintain ideal vibration isolation. Overloading compromises the table’s ability to reduce ambient vibrations by up to 90%.

Second, utilize the generous dimensions of platforms like 1200x800mm strategically. Position heavier components toward the center of your vibration-free floating table setup to preserve balance and stability. This arrangement maximizes the effectiveness of the pneumatic isolators.

Finally, consider the materials of both your equipment and the table. The 304 stainless steel construction facilitates cleaning while providing a stable foundation for sensitive camera systems.

Verify all components are securely fastened but not overly tight, allowing the isolation system to function properly.

Maintenance and Calibration of Vibration Isolation Systems

Maintaining peak performance of your vibration isolation system requires consistent attention to detail and regular calibration schedules.

Peak vibration isolation performance demands unwavering attention to detail and disciplined calibration routines.

You’ll need to check pneumatic mounts and isolators frequently to prevent excessive vibrations from affecting your sensitive equipment.

- Check and adjust each isolator’s level within ±0.25 inches (6mm) to maintain proper alignment

- Measure your system’s natural frequency and damping characteristics during calibration

- Inspect frame integrity and mounting components to prevent devastating equipment failure

- Document all maintenance procedures meticulously for regulatory compliance

- Perform preventative adjustments before performance deteriorates, not after

Remember that proper maintenance of vibration isolation systems isn’t just about performance—it’s about protecting your investment in precision equipment.

Regular calibration guarantees your floating table setup continues to provide the stable, vibration-free environment your work demands.

Cost-Benefit Analysis of Different Isolation Solutions

How much should you invest in vibration isolation for your laboratory? When evaluating vibration-free floating table setups, consider both immediate costs and long-term value. High-quality isolation platforms may require larger upfront investment but can reduce equipment maintenance costs by up to 90% while greatly improving measurement accuracy.

Passive air mounts offer a budget-friendly entry point, though they might underperform in dynamic environments. For critical applications, advanced solutions with pneumatic isolators and active damping systems deliver superior performance that justifies their higher price point.

Your specific equipment needs and operational environment should guide your decision. Remember that enhanced precision leads to quicker, more reliable results—often making premium isolation solutions cost-effective despite their higher initial investment.

The productivity gains and reduced error rates typically outweigh the costs.

Frequently Asked Questions

What Is the Purpose of the Anti-Vibration Table?

The anti-vibration table helps you protect your sensitive equipment by dampening external vibrations. It’ll isolate your instruments from environmental disturbances, ensuring accurate measurements and reliable performance for your precision laboratory work.

What Is the Purpose of a Vibrating Table?

You’ll use a vibrating table to consolidate materials like concrete, ensuring uniform distribution, reducing air pockets, and achieving higher density. It’s adjustable for different materials, enhancing product quality through controlled vibrations.

What Is a Vibration Isolation Table?

A vibration isolation table is your solution for protecting sensitive equipment from external disturbances. It’s designed with pneumatic mounts that absorb up to 90% of building vibrations, ensuring accurate measurements in laboratory settings.

What Is the Purpose of a Vibration Pad?

A vibration pad absorbs and dampens environmental vibrations, helping you protect sensitive equipment. You’ll achieve up to 90% reduction in building vibrations, ensuring accurate measurements and stable performance for your lab instruments.

In Summary

You’ve now seen how a vibration-free floating table setup is essential for precision microscopy. Whether you’re choosing pneumatic or mechanical isolation, proper sizing, or managing environmental factors, your investment protects delicate observations. Remember to maintain your system regularly and weigh the costs against your specific needs. With the right setup, you’ll eliminate unwanted vibrations and achieve the clear, stable images your research demands.

Leave a Reply