For ultra-precise specimen movement, you’ll get best results with piezoelectric actuators (sub-nanometer resolution) or repurposed optical drives from CD players. Microstepper motors offer more affordable precision at 1-10 micrometers. Enhance your setup with air bearings for frictionless movement, optical encoders for position feedback, and closed-loop control systems for stability. 3D-printed adapters can customize your stage for specific specimens. Arduino-based systems with the AccelStepper library deliver smooth, controlled motion for microscopy applications.

10 SECOND-LEVEL HEADINGS FOR “WHAT DIY STAGE CONTROLS GIVE ULTRA-PRECISE SPECIMEN MOVEMENT?”

Precision lies at the heart of effective specimen manipulation in microscopy. When building your DIY stage controls, you’ll need to focus on several key components that enable ultra-precise movement.

Your mechanical stages can achieve sub-micron resolution by incorporating micrometer screw drives, which offer exceptional control during delicate specimen handling.

Micrometer screw drives elevate DIY stages beyond hobbyist territory, delivering the sub-micron precision essential for critical specimen examination.

Enhance your system with high-resolution optical or capacitive encoders that provide real-time positioning feedback for improved accuracy.

For nanometer-level adjustments, consider integrating piezoelectric actuators that respond rapidly to electrical signals.

Frictionless linear bearings will minimize resistance, ensuring smoother translations across all axes.

Don’t overlook the control interface—customizable systems using Arduino or Raspberry Pi can be programmed to execute complex movement patterns, giving you versatility while maintaining precision that rivals commercial systems.

Essential Components for Building a Precision Stage Control System

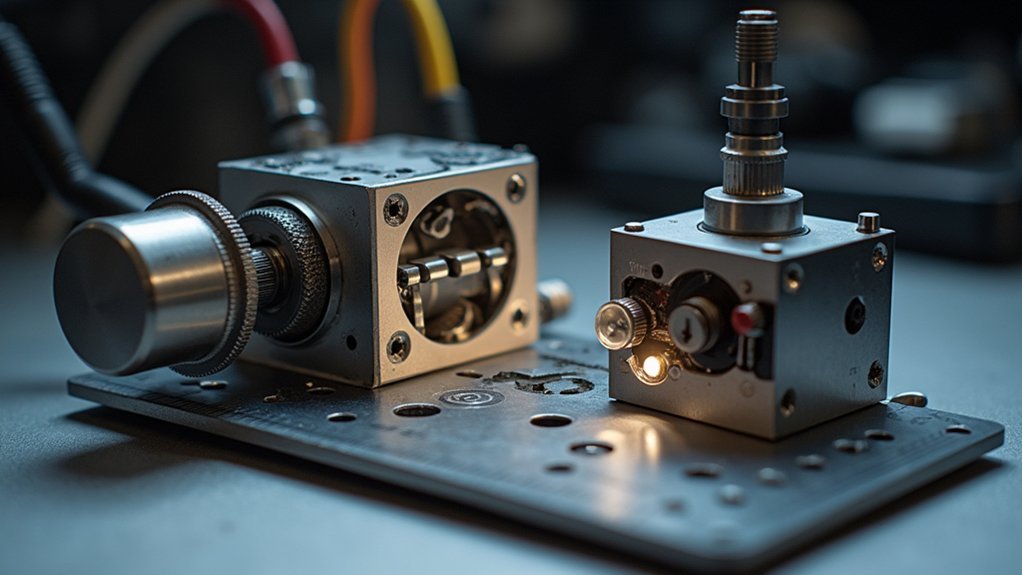

You’ll find DIY nanopositioning assemblies offer remarkable control at microscopic scales when you combine piezoelectric actuators with precision-machined components.

Flexure-based movement systems can provide sub-micron positioning accuracy through their spring-like structures that eliminate friction and backlash common in traditional bearings.

These specialized components complement standard motors and encoders, allowing your homemade stage control system to achieve professional-grade specimen manipulation for advanced microscopy applications.

DIY NANOPOSITIONING ASSEMBLIES

The heart of any effective specimen control system lies in its nanopositioning assembly. When building your own, you’ll want to incorporate piezoelectric actuators that provide sub-nanometer step sizes for precise slide holder positioning.

Start with a stable base stage, then add guiding mechanisms that guarantee perfectly linear movement. You can enhance performance by integrating air bearings, which create frictionless movement—a game-changer for ultra-precision work.

Don’t skimp on feedback components; high-quality optical encoders offer sub-nanometer resolution and improved stability for accurate specimen placement.

For peak control, implement digital controllers with real-time compensation capabilities that adapt to changing conditions.

FLEXURE-BASED MOVEMENT SYSTEMS

When designing high-precision specimen controls, flexure-based movement systems offer unparalleled advantages for DIY microscopy enthusiasts. You’ll achieve sub-nanometer positioning resolution essential for high magnification work while eliminating mechanical wear that plagues traditional systems.

By incorporating piezo actuators into your flexure-based movement systems, you’ll gain rapid response times for quick specimen adjustments. The frictionless design eliminates backlash, dramatically improving positioning repeatability during critical observations.

- Sub-nanometer resolution perfect for cellular structure examination

- No mechanical wear means longer service life for your DIY setup

- Backlash-free operation provides true position feedback

- Closed-loop control systems maintain stability during extended viewing sessions

For the ultimate DIY microscope stage, these flexure-based components deliver professional-grade precision without compromising your budget or fabrication capabilities.

Microstepper Motors vs. Piezoelectric Actuators for DIY Applications

When selecting between microstepper motors and piezoelectric actuators for your DIY specimen stage, you’ll face a fundamental tradeoff between the microstepper’s 1-10 micrometer precision versus the piezoelectric’s sub-nanometer resolution capabilities.

Your budget considerations will greatly impact this decision, as microstepper motors offer more affordable implementation with standard DC power supplies, while piezoelectric systems require specialized drivers and control electronics that increase overall costs.

The implementation complexity differs substantially, with microsteppers being more straightforward to integrate into hobbyist projects despite their slower response times, whereas piezoelectric actuators deliver microsecond responsiveness but demand more technical expertise to properly configure and control.

Precision Comparison Analysis

Selecting the right motion control technology for your DIY specimen stage requires careful evaluation of precision requirements against budget constraints.

When conducting a precision comparison analysis, you’ll find microstepper motors offer moderate precision at 1.8° per step (refinable to 0.01mm movements through microstepping), while piezoelectric actuators deliver sub-nanometer resolution with faster response times.

- Piezoelectric actuators achieve micrometer-range adjustments with sub-nanometer precision—100× finer than microstepper motors

- Microstepper motors operate at 100-500 steps/second, while piezoelectric systems respond at >1kHz frequencies

- You’ll get better load capacity and travel distance with microsteppers, despite their lower precision

- Piezoelectric systems offer superior compactness and lightweight design, essential for confined experimental setups

Your choice ultimately depends on whether your application prioritizes extreme precision or affordability and load capacity.

Cost-Benefit Tradeoff Assessment

Although both technologies enable precise specimen movement, the cost-benefit analysis between microstepper motors and piezoelectric actuators presents clear distinctions for DIY enthusiasts.

You’ll find microstepper motors exceptionally budget-friendly at $20-$100, making them ideal for educational projects and basic applications. Their 1.8-degree step resolution delivers adequate precision for many DIY needs without breaking the bank.

In contrast, piezoelectric actuators require a significant investment ($100-$500+) but deliver sub-nanometer precision and acceleration up to 10,000g. This cost-benefit tradeoff assessment hinges on your specific requirements.

Consider your project’s precision needs and budget constraints when deciding. Choose microsteppers when cost sensitivity outweighs precision requirements, but invest in piezoelectric systems when ultra-fine movement control and rapid response justify the higher expense.

Implementation Complexity Factors

As you immerse yourself in implementation considerations, the complexity gap between these two technologies becomes immediately apparent.

Microstepper motors offer a much gentler learning curve for DIY enthusiasts, requiring only basic electronics knowledge and readily available control boards.

- Piezoelectric systems demand specialized high-voltage drivers and complex tuning parameters.

- Microstepper motors connect directly to affordable Arduino shields with minimal configuration.

- Error handling in piezo systems requires advanced feedback mechanisms and calibration.

- Software implementation for microstepper motors uses widely available libraries and simple command structures.

While microstepper motors sacrifice some precision, their straightforward implementation means you’ll achieve functional results faster.

The complexity premium of piezoelectric systems only pays off when sub-nanometer precision is absolutely necessary for your specimen observation needs.

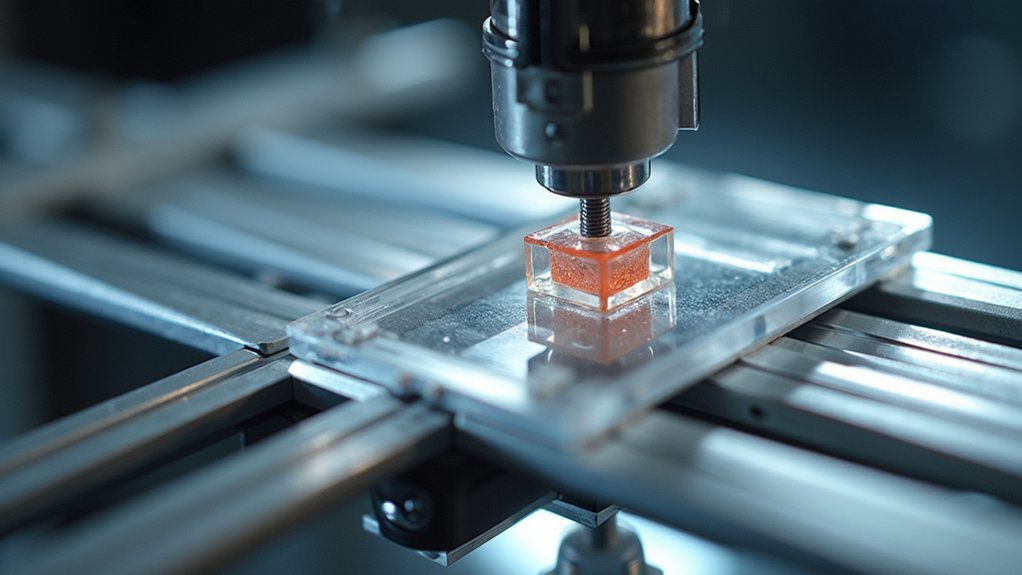

Designing Low-Cost XYZ Translation Mechanisms With Sub-Micron Accuracy

When you’re building microscopy equipment on a budget, achieving sub-micron accuracy doesn’t necessarily require expensive commercial solutions. You can create effective XYZ translation mechanisms using precision components like linear guides and ball screws paired with high-resolution encoders.

Consider integrating piezoelectric actuators for nanometer-scale adjustments that provide fine-tuning capabilities. Design your system with a modular approach, ensuring easy maintenance while preserving alignment accuracy.

Implement closed-loop control systems with feedback from optical encoders or capacitive sensors to enhance positioning repeatability. Don’t overlook the potential of 3D printing for custom components—it’s cost-effective and allows you to create complex geometries that optimize movement precision.

Repurposing Optical Drives for High-Resolution Specimen Positioning

You’ll find that optical drives from old CD players offer an unexpectedly precise platform for microscope stage control, with their stepper motors providing movement resolution finer than 0.1mm.

The linear rail systems originally designed to position laser assemblies can be repurposed to create smooth, controlled specimen translations along X and Y axes.

CD Mechanics Meet Microscopy

Three revolutionary components from optical CD drives make them perfect candidates for microscopy applications: stepper motors, linear actuators, and laser tracking systems.

When you’re building an optical microscopy setup, you’ll find these components deliver sub-micrometer positioning precision that would typically cost thousands in commercial equipment.

- Ultra-precise movement – Achieve 1-2 micrometer resolution for detailed specimen examination

- Cost-effective alternative – Transform $5 discarded drives into high-resolution positioning systems

- Easy microcontroller integration – Connect directly to Arduino or similar controllers for automated scanning

- Customizable stages – Design specimen holders tailored to your specific research needs

You’re essentially recycling the same precision engineering that reads microscopic pits on CDs into a system that can reliably position your specimens for detailed microscopic observation.

Stepper Motor Slide Control

Optical drive stepper motors serve as the cornerstone of DIY microscope stage controls, delivering precision that rivals commercial systems at a fraction of the cost. You’ll find these motors can achieve positioning resolution as fine as 1.8 micrometers per step, making them ideal for detailed specimen examination.

When you repurpose optical drives, you’re not just salvaging the stepper motors but utilizing the entire mechanical assembly including gears and rails. This integration creates an ultra-precise movement platform for your specimens.

For even greater accuracy, implement microstepping techniques to divide each full step into smaller increments, resulting in smoother motion and finer adjustments.

Pair your setup with an Arduino or Raspberry Pi to program customized movement sequences, and consider adding optical encoders for real-time position feedback and correction during your observations.

Arduino-Based Control Systems for Automated Microscope Stages

While commercial automated microscope stages often come with hefty price tags, Arduino-based control systems offer an affordable alternative without sacrificing precision. You’ll achieve movements as fine as 1 micron using stepper motors controlled through custom scripts in the Arduino IDE.

- Enhance positioning accuracy with optical encoders for sub-micron resolution

- Utilize the AccelStepper library for smooth acceleration and deceleration

- Create repeatable automated movements for consistent experimental results

- Implement user-friendly interfaces through LCD screens or web controls

Arduino-based control systems give you complete customization over your microscope’s movement patterns. By programming specific routines, you’ll automate complex scanning patterns that would be tedious to perform manually.

Unleash automated precision with Arduino, transforming tedious microscopy tasks into elegant programmed sequences at a fraction of commercial costs.

The combination of affordable hardware and open-source software makes precision microscopy accessible to researchers with modest budgets.

3D-Printed Solutions for Custom Microscope Stage Adapters

When traditional microscope stages fail to accommodate your unique specimens, 3D-printed adapters offer the perfect solution for precise positioning and movement control.

You’ll find these custom solutions integrate seamlessly with your existing microscope hardware while adding minimal weight to your stage mechanism.

The real advantage of 3D printing lies in rapid iteration—you can design, test, and refine your adapter in days rather than weeks.

Add specialized features like alignment guides or measurement markings directly into your design to enhance precision during observations.

Your adapter can be tailored to cradle specific specimen shapes and sizes, drastically improving stability during microscopic examination.

For researchers requiring ultra-precise movement control, these lightweight yet durable adapters guarantee smoother stage shifts while maintaining compatibility across various microscope models.

Implementing Closed-Loop Feedback for Enhanced Positioning Precision

To achieve truly professional-grade precision in your DIY microscope stage, implementing closed-loop feedback systems represents a notable leap forward.

By continuously monitoring actual stage position through sensors like optical encoders or capacitive detectors, you’ll transform your setup’s capabilities from basic to exceptional.

Your closed-loop feedback implementation delivers:

- Sub-nanometer resolution compared to standard open-loop systems

- Real-time position correction that eliminates drift and vibration effects

- Advanced digital controllers that minimize overshoot during specimen positioning

- Remarkably improved experimental repeatability for consistent results

You’ll notice immediate improvements in stability and accuracy when working with sensitive specimens.

This approach mirrors professional systems used in semiconductor manufacturing, allowing you to conduct high-resolution imaging with confidence that your specimens remain precisely where you’ve positioned them.

Cost-Effective Materials and Bearings for Smooth Stage Movement

Building a high-performance microscope stage doesn’t require breaking the bank, since carefully selected affordable materials can deliver professional-grade results.

You’ll find aluminum and high-density plastics offer excellent rigidity while keeping weight and costs low.

For truly smooth movements, incorporate linear ball bearings or sliding bearings into your design. These components dramatically improve motion precision during critical observations.

Consider using PTFE (Teflon) for contact surfaces to minimize friction and enhance control.

PTFE dramatically reduces friction, giving your microscope stage the buttery-smooth movement essential for precise specimen positioning.

A rack-and-pinion mechanism paired with quality bearings gives you the fine-tuning capability needed for high-magnification work.

Standardized components like 1/4-20 threaded rods and nuts make assembly straightforward while ensuring parts remain easily replaceable.

These cost-effective materials and thoughtfully selected bearings will transform your DIY stage into a precision instrument capable of ultra-precise specimen positioning.

Calibration Techniques for Verifying DIY Stage Performance

Once your DIY stage is built, proper calibration becomes vital for guaranteeing reliable performance and accurate specimen positioning. Effective calibration techniques validate that your microscope stage translates precisely along all axes, providing the ultra-precise control needed for detailed observations.

- Use precision optical encoders to measure actual movement distances compared to input commands.

- Compare your DIY stage against a micrometer stage reference to identify alignment issues.

- Check movement linearity by testing predetermined setpoints with calibrated rulers or digital calipers.

- Implement capacitive sensor feedback systems for real-time position monitoring.

Don’t overlook repeatability testing—it’s essential to verify your stage can return to the same position multiple times with minimal variance.

This thorough approach to calibration guarantees your DIY microscope stage delivers the accuracy needed for professional-level microscopy work.

Frequently Asked Questions

What Moves the Stage to Provide General Focus on the Specimen?

You’ll use the coarse focus knob to move the stage for general focus on your specimen. This provides larger vertical adjustments, quickly bringing the object into view before fine-tuning with the fine focus.

What Do You Use to Move the Stage on a Microscope?

You’ll use coaxial mechanical knobs on the microscope to move the stage. These controls allow precise X and Y directional adjustments through a rack-and-pinion gear system as you position your specimen for observation.

What Are the XY Stage Control Knobs?

XY stage control knobs are the dials you’ll find on your microscope’s mechanical stage. They allow you to precisely move your specimen slide horizontally (X-axis) and vertically (Y-axis) during observation.

What Part of the Microscope Accurately Controls the Movement of Slides?

The mechanical stage accurately controls your slide’s movement. You’ll find coaxial knobs that let you precisely adjust in X and Y directions, while rack-and-pinion gears guarantee smooth manipulation during high-magnification observations.

In Summary

You’ve now explored numerous DIY options for ultra-precise specimen movement systems. Whether you choose piezoelectric actuators, modified optical drives, or 3D-printed solutions, your success depends on proper calibration and feedback implementation. Don’t underestimate the importance of quality bearings and materials. With careful design and the right components, you’ll achieve sub-micron precision without breaking the bank—opening new possibilities for your microscopy projects.

Leave a Reply