Precision stage controls are essential for scientific imaging because they enable sub-nanometer resolution, extraordinary stability, and repeatable positioning. You’ll capture critical molecular interactions and reveal hidden structures with piezoelectric actuators and capacitive sensors working together. Multi-axis systems enhance your 3D navigation capabilities while minimizing noise and drift. Whether you’re using super-resolution microscopy or conducting dynamic imaging, the right positioning technology transforms your ability to visualize microscopic worlds in unprecedented detail.

Fundamental Principles of Stage Positioning in Microscopy

Three critical elements define effective stage positioning in modern microscopy: precision, speed, and stability. When you’re capturing high-resolution images, sub-nanometer resolution becomes essential, not optional. This precision is achieved through advanced piezo actuators that respond in milliseconds, allowing you to rapidly acquire complex image sets.

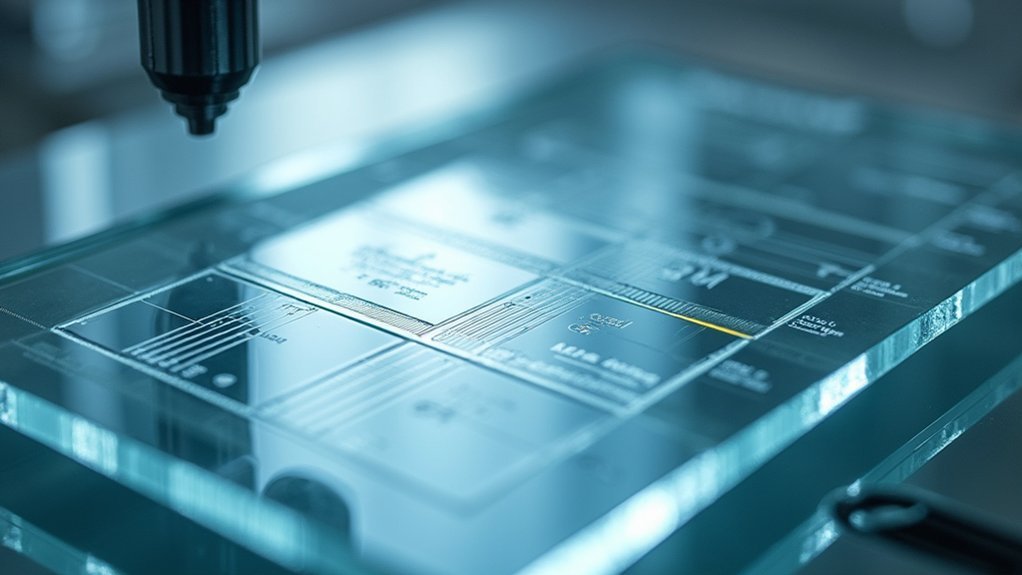

Modern XY stages incorporate capacitive sensors that guarantee positioning accuracy while minimizing noise—critical when you’re examining structures at the cellular or molecular level. The integration of multi-axis controls gives you versatility to navigate samples in three dimensions, enhancing your imaging capabilities.

The relationship between positioning precision and image quality is direct: superior stage control translates to sharper, more reliable scientific results that you can confidently use for analysis and publication.

Key Technologies Driving Nanopositioning Accuracy

Piezoelectric actuators form the foundation of today’s most advanced nanopositioning systems, delivering the sub-nanometer resolution you need for cutting-edge microscopy.

These piezo positioning stages integrate capacitive feedback sensors that guarantee high linearity and minimal noise, critical for super-resolution techniques.

You’ll benefit from direct-drive linear motors and voice coil technologies that achieve millisecond response times, enabling rapid focusing during complex imaging tasks.

Modern nanopositioning stages feature low-profile designs with large apertures, providing high stability across multiple axes.

For ultimate precision positioning, optical encoders deliver real-time feedback that assures repeatability in your most demanding experiments.

This combination of high precision technologies transforms challenging applications like atomic force microscopy from merely possible to consistently reliable, pushing the boundaries of scientific imaging forward.

Multi-Axis Control Systems for 3D Sample Navigation

Maneuvering complex biological specimens requires precision movement across multiple axes—a capability that transforms how you explore microscopic structures. When you’re conducting scientific research with high-resolution imaging techniques like confocal microscopy, multi-axis control systems deliver the navigation precision you need.

- Advanced positioning systems featuring piezoelectric actuators provide sub-nanometer resolution, dramatically improving your 3D reconstructions.

- Dynamic adjustments across X, Y, and Z directions enable detailed structural captures at varying sample depths.

- High-performance multi-axis stages like hexapods offer superior stability during fast imaging sequences.

- Custom-optimized positioners streamline your workflow in complex studies, reducing time between captures.

You’ll experience dramatically improved sample visualization when these precision controls work together, revealing structural details previously hidden from view.

Piezoelectric vs. Motorized Stages: Comparative Analysis

When selecting the ideal stage system for your scientific imaging applications, understanding the fundamental differences between piezoelectric and motorized technologies becomes critical to achieving your research objectives.

Piezoelectric stages deliver sub-nanometer resolution perfect for super-resolution microscopy and AFM, with millisecond response times that excel in Z-stack acquisition and fast scanning applications.

While motorized stages offer extended travel ranges and higher payload capacities, they can’t match the positioning accuracy of piezoelectric systems, particularly when speed matters.

You’ll find piezoelectric options eliminate the mechanical backlash common in motorized stages’ lead screws, providing frictionless motion and superior stability.

Piezomotor technology also presents advantages in compact design and minimal heat generation—crucial factors for maintaining system longevity in high-resolution imaging setups.

Impact of Stage Precision on Super-Resolution Imaging

The difference between capturing a groundbreaking image and missing critical molecular interactions often comes down to your stage’s precision capabilities.

When working with super-resolution microscopy, nanometer-level precision motion becomes essential for revealing structures conventional techniques can’t detect.

Your high-resolution microscopes require extraordinary position stability that only piezo stages with capacitive sensors can deliver.

These systems enable:

- Sub-nanometer resolution for visualizing intricate biological details

- Fast response times for efficient Z-stack acquisition and dynamic imaging

- Repeatable positioning with closed-loop feedback for consistent results

- Quick focusing capabilities through integrated Z-stages and objective positioners

Real-Time Feedback Mechanisms in Advanced Stage Control

Modern scientific imaging relies on closed-loop position correction systems that instantly detect and compensate for positional errors at the sub-nanometer level.

You’ll find these real-time feedback mechanisms incorporate sophisticated vibration compensation systems that actively counteract environmental disturbances, ensuring image stability even in challenging conditions.

The integration of high-resolution optical encoders and capacitive sensors enables these systems to respond within milliseconds, dramatically improving imaging results in applications requiring extreme precision like super-resolution microscopy.

Closed-Loop Position Correction

As scientific imaging demands ever-higher precision, closed-loop position correction systems have become essential components of advanced stage control technology.

These systems utilize real-time feedback to achieve sub-nanometer accuracy vital for your high-resolution imaging needs. You’ll find capacitive sensors at work, monitoring and adjusting stage positions with high linearity and minimal noise.

When you’re capturing super-resolution microscopy images, you need:

- Rapid response times in the low millisecond range

- Considerably reduced settling times for efficient imaging workflows

- Enhanced stability that eliminates drift during critical image acquisition

- Reliable positioning that maintains calibration across multiple samples

Vibration Compensation Systems

Building on closed-loop positioning technology, vibration compensation systems take precision control to an extraordinary level. They actively counteract external disturbances through real-time feedback mechanisms, ensuring high stability during your most critical imaging processes.

You’ll achieve sub-nanometer precision as these systems continuously adjust microscope stage positioning in response to detected vibrations. Advanced stage control technologies incorporate sophisticated sensors and algorithms that monitor disturbances and apply instant corrections, markedly enhancing image quality.

When you’re working with super-resolution microscopy, these systems considerably reduce motion artifacts, revealing cellular structures with unprecedented clarity.

For applications requiring high-speed imaging of dynamic biological processes, vibration compensation becomes essential—allowing you to capture precise measurements even in challenging environments. This integration of active compensation transforms what’s possible in scientific imaging.

Sub-nanometer Error Detection

When imaging at the molecular level, sub-nanometer error detection represents the cornerstone of precise stage control technology. Your microscopy results depend on real-time feedback mechanisms that leverage capacitive sensors to maintain high precision during imaging sessions.

Advanced stage control systems employ:

- Digital servo controllers that settle in milliseconds for rapid adjustments

- Piezomotor technology that eliminates backlash and friction for stable positioning

- Optical encoders that guarantee sub-nanometer resolution without significant drift

- Dynamic correction capabilities essential for Super Resolution Microscopy

These technologies work in concert to provide the high-resolution microscopy capabilities you need.

The integration of these sophisticated feedback systems guarantees you’ll capture the most minute details in your samples, with positioning errors corrected instantaneously during the imaging process.

Application-Specific Requirements Across Scientific Disciplines

The demanding nature of scientific imaging across diverse disciplines necessitates precision stage controls tailored to specific applications.

You’ll find that super-resolution microscopy requires piezoelectric stages with sub-nanometer resolution and rapid response times, while electron microscopy demands exceptional stability to capture atomic-level details. In both fields, high-resolution imaging hinges on precision stage controls that eliminate drift and vibration.

For advanced microscopy applications like fluorescence and confocal imaging, motorized stages enable automated multi-dimensional data acquisition while maintaining positional accuracy.

Your research in biology might benefit from PInano® systems, while materials science applications often require six-axis positioners for complex sample manipulation.

Future Innovations in Microscope Stage Technology

As researchers push the boundaries of scientific imaging, next-generation microscope stage technologies are emerging with unprecedented capabilities.

You’ll soon benefit from advanced piezo nanopositioning systems offering sub-nanometer resolution for high-resolution microscopy applications.

- Ultrasonic motors with self-clamping capabilities will minimize drift, ensuring your precision imaging remains stable throughout extended observation periods.

- Integration of hexapod systems will provide 6-axis control, dramatically improving the dynamics of motorized microscope stages.

- Enhanced digital servo controllers will seamlessly integrate with various imaging software platforms.

- Miniaturized stage technology will maintain high precision while enabling applications in confined research environments.

These innovations aren’t just incremental improvements—they’re transforming how you’ll capture, analyze, and interpret microscopic data, opening new frontiers in scientific discovery.

Frequently Asked Questions

How Do Temperature Fluctuations Affect Precision Stage Performance?

Temperature fluctuations cause thermal expansion and contraction of stage components, reducing your positioning accuracy. They’ll create drift, affect sensor readings, and compromise repeatability—especially in nanometer-resolution applications where you’re tracking microscopic movements.

What Maintenance Schedule Ensures Optimal Stage Control Longevity?

You’ll need monthly calibration checks, quarterly lubrication, semi-annual belt/bearing inspections, and annual encoder verification. Don’t skip cleanings after heavy use. Following manufacturer’s guidelines while documenting all maintenance guarantees your stage controls last longer.

How Much Vibration Isolation Is Necessary for Nanometer Precision?

For nanometer precision, you’ll need vibration isolation systems reducing environmental vibrations by 95-99%. You should implement pneumatic tables, active dampening, and isolation platforms with resonant frequencies below 1-2Hz for ideal results.

Can Precision Stages Be Retrofitted to Older Microscope Systems?

Yes, you can retrofit precision stages to older microscopes. It’s often cost-effective compared to full replacement, though you’ll need compatible mounting interfaces and may require updated control systems for ideal performance.

What Software Compatibility Issues Arise With Third-Party Stage Controls?

You’ll face driver conflicts, API incompatibility, and communication protocol mismatches with third-party stage controls. They often lack proper SDK support and might not integrate with your existing imaging software’s automation features.

In Summary

You’ll find that precision stage controls aren’t just accessories—they’re essential foundations of scientific imaging. Whether you’re mapping cellular structures or analyzing nanomaterials, the quality of your research depends on nanometer-level positioning accuracy. By investing in advanced stage technology that matches your specific application needs, you’re not just improving image quality; you’re enabling discoveries that would otherwise remain beyond your reach.

Leave a Reply