Setting up an automated stage system requires careful assessment of your lab’s specific needs and workflow. Start by evaluating precision requirements, load capacity, and software compatibility with your existing microscope. Guarantee proper hardware integration by verifying communication protocols between controllers and drives. Regular calibration using certified standards will maintain accuracy, while scheduled maintenance prevents downtime. Don’t overlook proper grounding to minimize interference. This methodical approach will transform your imaging capabilities and experimental throughput.

Setting Up Your Lab’s Automated Stage System

While manual microscopy setups have served scientists well for decades, an automated stage system represents a significant upgrade for any modern laboratory.

You’ll experience immediate efficiency gains through precise, repeatable sample positioning that eliminates handling errors common in manual processes.

When integrating your system, guarantee compatibility with your existing lab automation platforms. Most systems work seamlessly with various microscopy setups, requiring minimal modifications to your current equipment.

Program your automation system to perform complex procedures like z-stacking or time-lapse imaging for consistent, high-quality data collection.

Automate complex imaging sequences for reproducible results and enhanced data consistency across all your microscopy experiments.

Remember that your investment requires regular maintenance and calibration to maintain accuracy.

Assessing Your Lab’s Requirements for Stage Automation

Before purchasing an automated stage system, you’ll need to conduct a thorough assessment of your laboratory’s specific requirements. Start by identifying which lab processes would benefit most from automation—whether it’s sample tracking, preparation procedures, or analysis workflows.

Evaluate the types of data your system needs to manage and ascertain the automation solution can efficiently handle these requirements. Consider how the new system will integrate with your existing hardware and software infrastructure to maintain seamless operations.

Establish clear objectives for your automation implementation, such as increasing throughput, minimizing errors, or improving result consistency.

Don’t forget to involve all stakeholders in this assessment phase, gathering input from lab personnel and management to ensure the system you select aligns with broader operational goals.

Key Components of an Automated XY Stage System

The foundation of any automated stage system centers on several critical components working in harmony to deliver precise sample positioning. Your automated systems will require both precision motors—typically stepper or servo types—and sophisticated encoders that provide feedback for micrometer-level accuracy.

| Component | Hardware | Software |

|---|---|---|

| Motors | Stepper/servo drives | Motion control algorithms |

| Positioning | Encoders & sensors | Real-time feedback systems |

| Interface | Sample holders & mounts | User dashboard & programming tools |

The control software forms the brain of your system, allowing you to program complex movement patterns and integrate with other lab equipment. Look for systems with intuitive interfaces that enable you to monitor positioning in real-time and make adjustments as needed, enhancing your workflow efficiency in microscopy or materials testing applications.

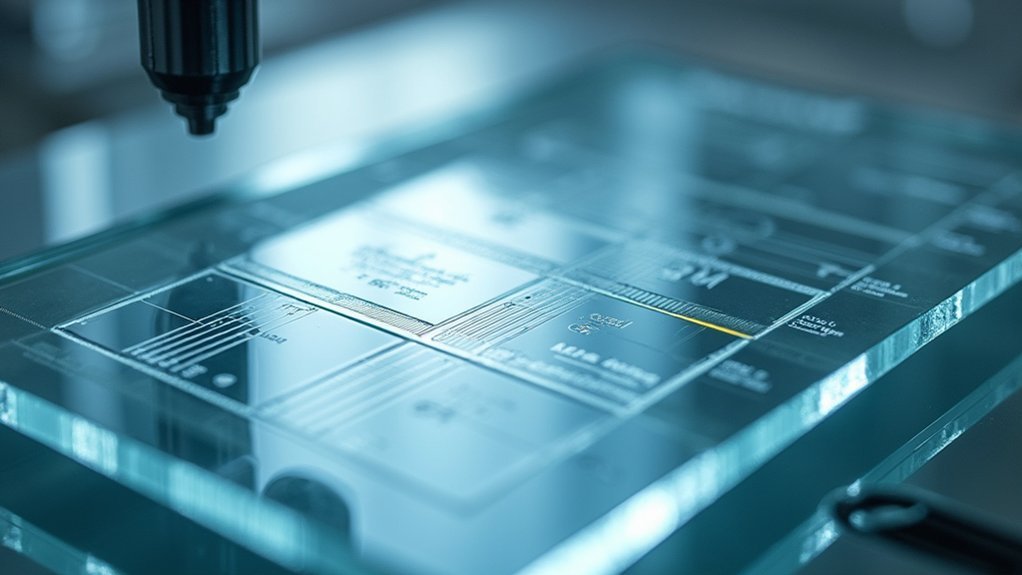

Selecting the Right Motorized Stage for Your Microscope

How effectively you’ll capture precise images depends largely on selecting a motorized stage that perfectly matches your microscope’s specifications.

Check compatibility first, as mounting requirements vary between microscope models.

Before investing in a motorized stage, ensure it physically fits your microscope system—incompatible mounting specifications waste both time and resources.

Prioritize precision—look for stages offering movement control measured in micrometers for accurate sample positioning.

Don’t overlook speed and responsiveness, especially if you’re running high-throughput operations where efficiency matters.

Consider software integration capabilities with your existing imaging software or LIMS to streamline workflow and data management.

This integration will save you considerable time during complex imaging sessions.

Finally, verify the stage’s load capacity can adequately support your microscope and accessories without performance degradation.

A stage that struggles under weight will compromise the precision you’re working to achieve.

Hardware Integration: Connecting Controllers and Drives

Properly connecting your controllers and drives requires careful attention to wiring configurations and pinouts to guarantee reliable communication between components.

You’ll need to select the appropriate communication protocol (USB, RS-232, or Ethernet) based on your specific hardware compatibility requirements and laboratory setup constraints.

Don’t forget to implement proper grounding techniques to minimize electromagnetic interference that could compromise your automated stage system’s precision and performance.

Hardware Integration: Connecting Controllers and Drives

Successfully integrating your automated stage system requires establishing reliable connections between controllers and drives, which form the backbone of your laboratory automation.

When setting up your hardware integration, select controllers and drives that are fully compatible to maintain system integrity and guarantee precise control over automated processes.

Connect your components using standardized communication protocols like USB, RS-232, or Ethernet to assure reliable data transfer across your automation systems.

Always verify that power requirements and electrical specifications match for all connected devices to prevent performance issues during operation.

Don’t overlook the importance of regular firmware and software updates for your controllers and drives.

These updates guarantee ongoing compatibility with evolving automation technologies and provide critical performance improvements that keep your lab’s stage system running effectively.

Wiring Configurations and Pinouts

Precision in wiring configurations and pinouts forms the critical foundation for your automated stage system’s reliability.

When establishing connections between controllers and drives, you’ll need to carefully match the controller’s pinout specifications with your drive’s input requirements.

For successful implementation, follow these key steps:

- Consult the manufacturer’s documentation for specific pinout diagrams, as configurations vary between models.

- Implement color-coded wiring standards (red for positive, black for ground) to prevent connection errors.

- Use a multi-meter to test connections and verify voltage levels before system power-up.

- Document all wiring configurations and modifications for future troubleshooting.

Maintaining organized records of your wiring configurations will save valuable time when you need to modify or troubleshoot your system.

This careful approach guarantees proper communication between components and protects your investment.

Communication Protocols Setup

With your physical wiring properly organized, you’ll now need to establish functional communication channels between your controllers and drives to create a responsive automated stage system.

Select appropriate interfaces like USB, RS-232, or Ethernet, ensuring hardware compatibility throughout your automation system.

Implement standardized communication protocols such as TCP/IP or Modbus to enhance interoperability and reliability.

Configure essential communication parameters—baud rates, data bits, stop bits, and parity settings—on both controllers and drives for seamless operation.

Don’t overlook error-checking mechanisms like checksums or CRC to maintain data integrity during transmission.

These tools help identify and correct potential errors before they affect system performance.

Finally, keep your controllers and drives updated with the latest firmware to maintain compatibility with evolving communication standards.

Software Selection for Precise Stage Positioning Control

The right software serves as the brain of your automated stage system, translating your experimental requirements into precise mechanical movements. When selecting positioning control software for your lab’s automation needs, focus on capabilities that will enhance both accuracy and workflow efficiency.

- Hardware compatibility – Choose software that integrates seamlessly with your existing microscopy and imaging hardware to prevent communication bottlenecks.

- Positioning precision – Look for real-time feedback and closed-loop control features that minimize drift during extended imaging sessions.

- Customization options – Prioritize platforms supporting user-defined protocols and automation scripts tailored to your specific experimental workflows.

- User experience – Select software with intuitive interfaces and detailed documentation to reduce training time and increase adoption among your team members.

Calibration Procedures for Optimal Stage Performance

Achieving reliable experimental results depends fundamentally on proper calibration of your automated stage system. You should perform this calibration before each use to guarantee precise sample positioning and movement accuracy.

Start by using calibration standards with known dimensions to verify your stage’s movement precision. Make necessary adjustments to minimize any discrepancies you observe.

Always begin with certified calibration standards to verify positioning accuracy and make immediate adjustments when deviations emerge.

Take advantage of software tools offering real-time feedback during the calibration process—these will help you detect and correct misalignments immediately.

Document every calibration session, including date, results, and adjustments made. This record-keeping creates a valuable performance history and simplifies troubleshooting when issues arise.

Don’t overlook regular maintenance of mechanical components like motors and guides, as wear can impact your automated system’s calibration accuracy over time.

Programming Movement Sequences and Position Memory

Programming your automated stage system starts with understanding Cartesian coordinate systems that map X, Y, and Z positions for precise sample localization.

You’ll need to develop script-based movement patterns that optimize travel paths between experimental regions while minimizing mechanical wear.

Implementing save-load position protocols will let you store frequently used locations, ensuring consistent results across multiple experimental runs without manual repositioning.

Coordinate System Fundamentals

While scientists often focus on sample preparation and analysis protocols, mastering your automated stage’s coordinate system fundamentals forms the backbone of reliable experimental workflows.

Your stage’s coordinate system provides the spatial framework that guides all movement operations in your laboratory setup.

To effectively implement your coordinate system:

- Establish a consistent Cartesian grid (X, Y, Z) that aligns with your experimental workspace and equipment orientation.

- Define reference points or “home” positions that serve as anchors for programming movement sequences.

- Utilize position memory features to store frequently accessed coordinates, eliminating repetitive programming.

- Incorporate feedback mechanisms like encoders to maintain positioning accuracy during experimental runs.

Understanding these fundamentals enables precise navigation through your experimental space and guarantees reproducible results across multiple sessions.

Script-Based Movement Patterns

The foundation of efficient laboratory automation lies in mastering script-based movement patterns for your automated stage system. By programming precise movement sequences, you’ll create reproducible workflows that eliminate human error and boost consistency across experiments.

Your workflow can be automated using various programming languages to define specific coordinates and shifts between critical positions. Position memory features allow your system to store multiple predefined locations, enabling quick shifts between experimental tasks without manual intervention.

Implementing these scripted patterns greatly reduces experiment duration, as your system executes repetitive movements automatically. This automation increases your lab’s throughput while maintaining experimental integrity.

The time you invest in programming these sequences pays dividends through enhanced productivity and reliability—turning your automated stage into a powerful asset for consistent laboratory procedures.

Save-Load Position Protocols

Leveraging save-load position protocols greatly streamlines your workflow by creating a digital memory bank of critical stage positions.

These protocols enable your automation system to memorize complex movement patterns, eliminating repetitive manual calibrations and reducing human error in your lab’s processes.

- Program specific coordinates for frequently accessed positions, allowing your system to return to exact locations with consistent accuracy.

- Store multiple position sequences to support various assay requirements, maximizing flexibility across different protocols.

- Execute complex workflows seamlessly by chaining saved positions into complete experimental routines.

- Customize movement parameters for each saved position, optimizing speed and precision based on task requirements.

When automation comes with position memory capabilities, you’ll greatly reduce setup time between tasks while ensuring reproducible results across experiments.

Setting Up Multi-Position Imaging Workflows

Many researchers consider multi-position imaging workflows the backbone of high-throughput microscopy experiments. By implementing an automated stage system, you’ll dramatically increase throughput by capturing images from multiple sample locations simultaneously rather than sequentially.

For ideal results, integrate your imaging software with the stage controls to standardize exposure times and focus settings across positions.

Don’t overlook the importance of regular calibration—this quality control step guarantees consistent positioning accuracy and maintains data integrity across experiments.

Regular calibration is non-negotiable for maintaining positioning precision and safeguarding experimental data quality over time.

Consider implementing barcoding and tracking systems to streamline sample identification and minimize errors. These tools enhance traceability throughout your workflow, from acquisition to analysis.

With proper setup, your multi-position workflow will deliver precise, reproducible results while greatly reducing the time required for thorough imaging studies.

Troubleshooting Common Automated Stage Issues

When your automated stage exhibits connectivity failures, you’ll need to inspect all cables for secure attachment and visible damage, as loose connections often cause communication errors with the control system.

To prevent calibration errors that lead to positioning inaccuracies, implement a regular calibration schedule that aligns with your usage frequency and precision requirements.

You can identify potential issues before they escalate by running the system’s diagnostic software after completing high-precision imaging sessions or whenever you notice unusual stage behavior.

Connectivity Failures

Despite your best setup efforts, connectivity failures can quickly halt productivity in automated stage systems. When your system stops responding, follow this systematic approach to identify and resolve the issue:

- Check the basics first – verify all cables are securely connected and that every component has power. Loose connections are often the culprit behind most connectivity failures.

- Verify your software environment – outdated drivers or incompatible software versions can prevent proper communication with your automated stage system.

- Run manufacturer-provided diagnostic tools to pinpoint specific errors and assess system health more accurately.

- If your stage integrates with LIMS or other lab software, confirm that communication protocols are correctly configured for seamless data transfer.

Don’t forget to regularly update firmware and drivers to prevent future connectivity issues.

Calibration Error Prevention

Precise calibration stands as the foundation of reliable automated stage systems, yet even minor errors can cascade into significant experimental failures. Check your automated stage’s calibration regularly—ideally every few weeks or after making significant adjustments to your setup—following manufacturer guidelines.

Take advantage of real-time feedback software tools that immediately identify positioning discrepancies. When you notice alignment issues or inconsistent movements, inspect for improper stage alignment or misconfigured software settings.

Establish a routine maintenance schedule that includes cleaning mechanical components, as dust accumulation can interfere with precise movements.

Don’t overlook the importance of documentation—keep records of all calibration procedures and errors you encounter. This historical data will prove invaluable when troubleshooting recurring issues and will ultimately improve your system’s long-term reliability.

Maintenance Protocols for Long-Term System Reliability

To maximize the lifespan and performance of your automated stage system, you’ll need to implement extensive maintenance protocols. Regular attention to your equipment guarantees consistent results and prevents costly downtime in your automated processes.

Establish these essential practices:

- Schedule routine maintenance checks that include calibration and functionality testing of all automated components at least quarterly.

- Maintain a detailed logbook documenting all repairs, maintenance activities, and parts replacements.

- Perform regular software updates and backups to protect against vulnerabilities and guarantee peak system performance.

- Train your staff on basic troubleshooting techniques and routine maintenance tasks they can perform independently.

Don’t wait for equipment failure to address maintenance—preventative care is far more cost-effective than emergency repairs and helps maintain data integrity throughout your research.

Enhancing Precision With Feedback Mechanisms

While automated stage systems provide inherent advantages over manual operations, their true potential emerges when coupled with sophisticated feedback mechanisms.

By implementing closed-loop systems that utilize encoders and sensors, you’ll reduce positioning errors to less than 0.1 mm, enhancing your lab’s experimental repeatability.

These feedback mechanisms deliver real-time data on positional accuracy, allowing your system to make automatic adjustments that improve precision by up to 95% in critical applications.

You’ll notice markedly minimized drift during extended operations, ensuring consistent sample processing over time.

Consider integrating software that analyzes feedback data to identify performance trends.

This approach not only enables dynamic response adjustments as your equipment adapts to environmental changes but also facilitates predictive maintenance—optimizing system reliability while maintaining the high precision your research demands.

Advanced Applications: Tiling and 3D Reconstruction

Automated stage systems release remarkable capabilities beyond basic positioning, particularly in tiling and 3D reconstruction workflows. When integrated with sample management protocols, these systems transform your laboratory’s imaging capabilities:

- High-resolution mapping – Create extensive mosaic images with resolutions as fine as 0.1 micrometers, enabling detailed visualization of cellular structures during nucleic acid extraction procedures.

- Three-dimensional visualization – Generate detailed 3D models from image stacks, providing unprecedented insights into spatial relationships of specimens.

- Workflow automation – Program complex scanning protocols that reduce manual labor while increasing throughput for high-content screening.

- Real-time analysis – Integrate image processing software that interprets tiled images instantly, streamlining nucleic acid extraction workflows and enhancing laboratory productivity.

These advanced applications represent the cutting edge of automated microscopy, delivering powerful analytical capabilities to your research.

Frequently Asked Questions

What Is Laboratory Automation System?

Laboratory automation systems are tools you’ll use to streamline repetitive tasks in your lab. They’ll reduce human error, increase throughput through parallel processing, and integrate with existing instruments for seamless data management.

What Is an Automated Method in a Laboratory?

In a laboratory, an automated method means you’re using technology to perform repetitive tasks with minimal human input. You’ll benefit from reduced errors, increased efficiency, standardized protocols, and improved data tracking capabilities.

Which Two Technologies Are Used in Lab Automation?

In lab automation, you’ll primarily use robotics technology for sample manipulation and LIMS (Laboratory Information Management Systems) for data management. These work together to enhance your workflow efficiency and reduce manual errors.

In Summary

You’ve now mastered the essentials of lab stage automation. With proper setup, maintenance, and troubleshooting knowledge, you’ll maximize your system’s potential for years to come. Don’t underestimate the power of regular calibration and software updates. As you become more comfortable with your automated stage, you’ll discover new applications that will transform your research capabilities and experimental efficiency.

Leave a Reply