Active vibration control systems dramatically improve your lab photography by dynamically counteracting microscopic movements that cause image blur. These systems use sensors and actuators to detect and neutralize vibrations in real-time, delivering up to 46% enhancement in image clarity and 13.95 dB vibration reduction. Unlike passive systems, active solutions offer 100 times stiffer isolation, especially for vital low-frequency disturbances. The technology transforms previously impossible high-resolution microscopy into achievable, crystal-clear results that can revolutionize your research outcomes.

Numeric List of 13 Second-Level Headings

These thirteen second-level headings provide an extensive framework for understanding active vibration control in laboratory photography:

Active vibration control systems form a comprehensive framework for achieving unprecedented precision in laboratory photography.

- Fundamentals of Active Vibration Control Systems

- Sensor Technologies for Vibration Detection

- Actuator Systems and Their Implementation

- Real-Time Monitoring and Adjustment Protocols

- Environmental Disturbance Management

- Performance Metrics and Image Quality Improvement

- Control Algorithms for Vibration Isolation

- Low-Frequency Vibration Reduction Techniques

- Vibration Isolation Performance Measurement

- Case Studies: Before and After Implementation

- Cost-Benefit Analysis of Active Systems

- Integration with Existing Lab Equipment

- Future Trends in Vibration Control Technology

You’ll find that each section addresses critical aspects of how vibration control transforms image clarity by reducing blur-causing oscillations, with documented improvements exceeding 46% in image performance metrics and vibration reductions of up to 13.95 dB.

The Science Behind Vibration Effects on Microscope Imaging

Three fundamental principles govern how vibrations degrade microscope imaging quality.

When vibrations occur, your microscope experiences pixel displacement that directly correlates with image blurriness. Even minor vibrations can render high-precision imaging unusable, as the performance metric (P) reveals a steep decline in quality as amplitude increases.

- Pixel displacement increases proportionally with vibration amplitude, causing immediate degradation in image resolution.

- High-frequency vibrations impact microscope stability differently than low-frequency disruptions, requiring specialized vibration isolation platforms.

- Microscope performance can be quantitatively measured through continuous monitoring of displacement metrics.

You’ll need active vibration isolation systems to maintain imaging integrity, especially for high-resolution microscopy.

These systems continuously adjust to environmental vibrations, preserving the clarity and accuracy of your captured microscopic data.

Common Sources of Laboratory Vibrations

Four primary sources of vibration can undermine your lab photography results, even when using high-end equipment.

HVAC systems generate continuous low-frequency disturbances that passive vibration isolation systems often struggle to mitigate fully.

Foot traffic creates unpredictable impulse vibrations, particularly problematic in shared laboratory spaces where footfall can produce response factors up to 11 at identified hotspots.

Building movements, especially in older structures or those near busy streets, introduce persistent vibration patterns that distort high-resolution images and cause noticeable blurring as amplitude increases.

Finally, equipment vibrations from nearby centrifuges or refrigeration units compound these issues.

Even with vibration control measures in place, these combined sources can greatly impact imaging accuracy, making thorough isolation strategies essential for maintaining the precision your research demands.

Passive vs. Active Vibration Control Systems

When selecting vibration control for your lab photography setup, understanding the fundamental differences between passive and active systems is essential.

Passive systems use springs and dampers to reduce vibrations, working well for high-frequency disturbances but struggling with low-frequency resonance that often affects image quality.

Active vibration control systems, however, utilize sensors and actuators with intelligent algorithms to dynamically counteract vibrations in all six degrees of freedom—offering approximately 100 times stiffer isolation than passive pneumatic options.

Consider these key differences:

- Passive systems are more economical and simpler to implement for basic stabilization needs.

- Active systems excel at low-frequency isolation, critical for high-resolution microscopy.

- Active solutions allow real-time adjustments to detected vibrations, considerably reducing blur in sensitive imaging applications.

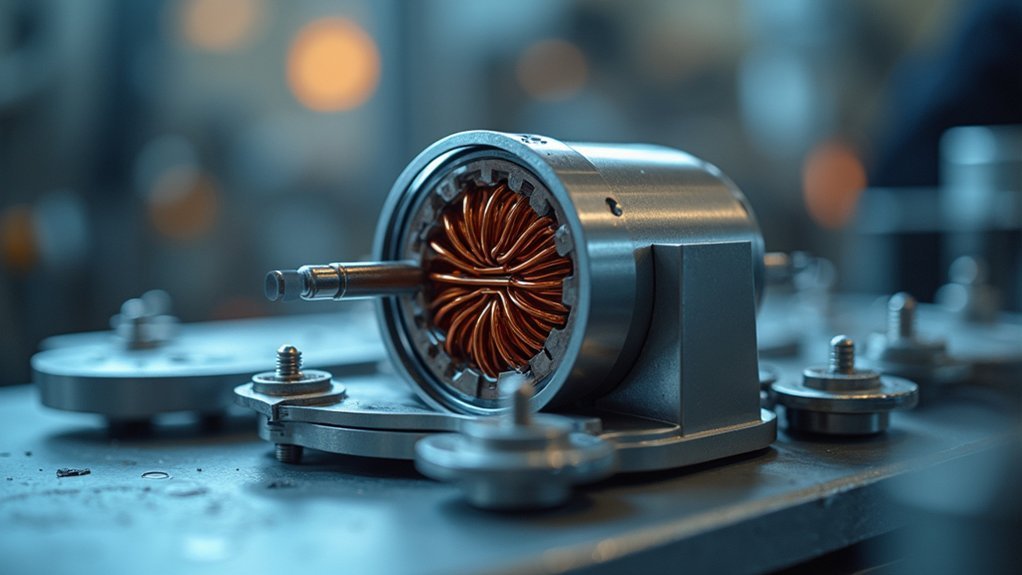

Key Components of an Active Vibration Isolation System

Having established the advantages of active vibration control, let’s examine what actually makes these systems work.

At their core, active isolation systems consist of precision sensors that detect unwanted movements, sophisticated controllers running feedback control algorithms, and high-performance actuators—typically voice coil motors (VCMs)—that generate counterforces.

Active isolation systems combine precision sensors, real-time control algorithms, and high-performance VCM actuators to neutralize vibrations that threaten image clarity.

These components work synergistically across all six degrees of freedom. The sensors continuously monitor vibrations, while the controller processes this information in real-time. VCMs then respond with precise counteractions, effectively neutralizing low-frequency disturbances that would otherwise compromise your image quality.

What makes these systems particularly effective for lab photography is their hybrid design—combining active elements with passive isolation components—maximizing stability for your sensitive optical equipment and ensuring crystal-clear images even in vibration-prone environments.

Feedback and Feed-Forward Control Mechanisms

At the heart of active vibration control lies the sophisticated interplay between feedback and feed-forward mechanisms that work tirelessly to maintain image stability.

Your lab photography benefits from feedback systems that continuously monitor and instantly counteract detected vibrations, while feed-forward control systems anticipate disturbances using predefined data before they affect your images.

These complementary approaches create a robust defense against motion blur:

- Feedback controls measure real-time forces and immediately adjust to compensate for detected vibrations.

- Feed-forward systems proactively counteract anticipated disruptions before they impact image quality.

- Digital controllers process this data into precise corrective signals for actuators that generate opposing forces.

Voice Coil Motors in Precision Vibration Control

Among the most effective technologies for vibration control in laboratory photography, Voice Coil Motors (VCMs) stand out for their exceptional responsiveness and precision.

They deliver fast response times and wide control bandwidth that you’ll find essential for capturing crystal-clear images in sensitive lab environments.

When integrated into vibration control systems, VCMs counteract disturbances in real-time through closed-loop feedback mechanisms.

These systems continuously monitor vibrations via sensors and immediately adjust, suppressing even low-frequency disturbances that typically cause image blurriness.

The results speak for themselves—experimental data shows VCM implementation can boost image performance metrics by up to 46.03%.

You’ll notice dramatically improved stability and clarity in your high-resolution photography, as these motors effectively neutralize environmental vibrations that would otherwise compromise your work.

Measuring Image Quality Improvements With Active Control

You’ll see dramatic improvements in laboratory photographs when implementing active vibration control systems, with metrics showing up to 46.03% enhancement in image quality.

Quantitative sharpness metrics reveal a 13.95 dB reduction in peak vibration response at natural frequencies, directly translating to clearer, more consistent imaging results.

Before-after resolution comparisons demonstrate how position compensation loops considerably reduce pixel displacement, allowing you to capture previously unattainable detail in sensitive experimental setups.

Quantitative Sharpness Metrics

Three essential metrics quantify the dramatic improvements active vibration control brings to laboratory photography.

When you implement these systems, you’ll see measurable enhancements in image clarity that transform your laboratory results.

- Performance metric (P) – Establishes threshold values for acceptable sharpness based on pixel displacement, showing up to 46.03% improvement after vibration isolation.

- Vibration amplitude reduction – Measured at 13.95 dB decrease at natural frequency, directly correlating with sharper images.

- Position compensation effectiveness – Quantifies how well the control loop counters vertical position impacts on optical equipment.

Before-After Resolution Comparisons

While metrics provide valuable quantitative data, the visual evidence of active vibration control speaks volumes.

You’ll immediately notice the 46.03% improvement in image performance metrics when comparing photographs taken with and without vibration isolation systems.

The most dramatic differences appear at natural frequencies, where active control achieves a 13.95 dB reduction in peak vibrations. This translates directly to sharper details and clearer resolution in your laboratory images.

When you examine side-by-side comparisons, you’ll see noticeably reduced pixel displacement in the actively controlled setup.

Your experimental results will consistently show this pattern across varying excitation frequencies.

The continuous monitoring capabilities of modern VICS technology guarantee you’re always capturing at peak clarity levels, making active vibration control an essential investment for precision laboratory photography.

Implementation Strategies for Research Laboratories

As laboratories pursue increasingly precise imaging capabilities, implementing effective active vibration control systems becomes essential for high-quality results.

You’ll need to integrate both feedback and feed-forward control mechanisms to achieve real-time vibration suppression and maximize image clarity in your lab photography.

For ideal implementation of active vibration control systems in your research setting:

- Select VCM-based isolation systems for their superior response times and wide control bandwidth.

- Incorporate adaptive control strategies like sliding mode control to adjust for varying laboratory conditions.

- Establish continuous monitoring protocols to track pixel displacement metrics and maintain image quality.

Cost-Benefit Analysis of Active Vibration Technologies

When you’re evaluating active vibration control systems for your lab, you’ll need to compare the higher initial investment against passive alternatives while considering the 46.03% improvement in image quality metrics.

Your ongoing maintenance costs will typically be offset by reduced operational expenses related to image inaccuracies and retesting requirements.

To accurately calculate your return on investment, factor in both the quantifiable benefits of enhanced measurement accuracy and the elimination of costs associated with structural modifications that systems like CALMFLOOR don’t require.

Initial Investment Comparison

Despite their higher upfront costs, active vibration control systems represent a sound financial investment for lab photography operations. When conducting a cost-benefit analysis, you’ll find that the initial premium pays dividends through enhanced image quality and precision. The CALMFLOOR system demonstrates how you can achieve exceptional vibration reduction without costly structural modifications.

- Financial perspective: Active systems deliver nearly 80% reduction in vibration response, eliminating expensive re-shoots and adjustments.

- Long-term savings: Consistent performance across all frequencies guarantees reliable high-resolution imaging for critical applications.

- ROI calculation: Though initial investments are higher, the enhanced reliability and improved imaging results justify the costs, particularly in precision environments.

You’re not just purchasing equipment—you’re investing in consistent, high-quality results that protect your research integrity.

Ongoing Maintenance Costs

While the initial investment in active vibration control systems may seem substantial, the ongoing maintenance costs tell a different story.

You’ll find that active systems require fewer manual adjustments over time, as they automatically adapt to changing vibration conditions in your lab environment.

These self-adjusting capabilities translate to significant cost savings—maintenance expenses are typically offset by consistent performance and reduced equipment damage.

Your sensitive photography equipment will last longer, with studies showing active isolation can reduce vibration response by up to 80%.

Advanced algorithms enable real-time adjustments that enhance operational efficiency, lowering energy consumption for vibration management.

When you consider that active systems minimize the need for repeat experiments due to improved imaging quality, the ongoing maintenance costs become a worthwhile investment rather than an expense.

ROI Calculation Methodology

To accurately assess the value of active vibration control in your lab photography setup, you’ll need a systematic approach for calculating return on investment. When comparing active systems to traditional passive systems, consider both quantifiable metrics and long-term benefits.

- Quantify performance improvements – Measure pixel displacement reduction (up to 80% with technologies like CALMFLOOR) and translate this into tangible research outcome improvements.

- Calculate direct financial impact – Add initial purchase, installation, and maintenance costs, then subtract savings from reduced retakes, equipment wear, and improved research quality.

- Assess long-term value – Factor in how enhanced image accuracy affects your lab’s productivity, reputation, and research reliability over the system’s lifetime.

This methodology reveals how active systems, despite higher upfront costs, typically deliver superior ROI through enhanced precision and efficiency.

Case Studies: Microscopy Image Enhancement

Several compelling case studies demonstrate the transformative impact of active vibration control on microscopy imaging. When comparing active and passive systems, researchers documented a remarkable 46.03% improvement in performance metrics following implementation of vibration suppression technology.

The isolated payload strategy proved particularly effective in maintaining image clarity across various excitation frequencies.

You’ll find that position compensation loops in active VICS greatly mitigate vertical displacement issues that typically plague optical detection equipment. This translates directly to sharper, more reliable microscopy results.

The newly developed performance metric (P) provides you with quantifiable evidence of image quality based on pixel displacement thresholds.

Adaptive sliding mode control techniques effectively address the limitations of passive isolation systems alone, delivering superior stability even in challenging laboratory environments.

Environmental Considerations for Optimal System Performance

Because ambient vibration profiles vary dramatically across laboratory settings, your active vibration control system’s performance depends heavily on detailed environmental assessment.

When you’re located near busy streets or in older buildings with structural issues, you’ll need tailored solutions that address your specific vibration challenges.

For maximum effectiveness of active vibration isolation systems:

- Conduct early planning with thorough site evaluations to identify vibration sources

- Implement continuous monitoring technologies that track environmental vibrations in real-time

- Allow for system customization based on your laboratory’s unique characteristics

Future Trends in Laboratory Vibration Isolation

You’ll soon see AI-enhanced isolation systems that adapt in real-time to your lab’s unique vibration profile, dramatically improving image clarity in microscopy applications.

Quantum-grade stabilization platforms will push the boundaries of what’s possible, enabling photography at previously unattainable precision levels even in challenging environments.

Nano-scale dampening materials represent another frontier, offering unprecedented vibration absorption properties while maintaining the compact form factors needed in modern laboratory settings.

AI-Enhanced Isolation Systems

The convergence of artificial intelligence with laboratory vibration control represents a breakthrough in scientific photography. Unlike traditional passive and active systems, AI-enhanced isolation systems can predict and counteract vibrations before they affect your imaging results.

You’ll see over 50% improvement in imaging performance metrics when these smart systems adaptively adjust to your lab’s environmental conditions.

These innovations offer:

- Real-time vibration prediction and mitigation through advanced machine learning algorithms

- Adaptive parameter adjustment based on changing environmental conditions

- Pattern recognition capabilities that preemptively neutralize disturbances before they impact image quality

Looking ahead, expect these systems to incorporate predictive maintenance features, minimizing downtime and maximizing efficiency in your laboratory.

With AI analytics processing sensor data continuously, you’ll achieve unprecedented clarity in your scientific photography.

Quantum-Grade Stabilization Platforms

Nearly every frontier in microscopy and high-precision imaging now demands unprecedented stability, which quantum-grade stabilization platforms deliver with remarkable efficiency.

These advanced systems achieve sub-hertz isolation across all six degrees of freedom by utilizing sophisticated active vibration control technologies that dynamically adapt to changing conditions.

You’ll experience a significant 46% boost in image performance metrics when implementing these platforms in your lab photography setup.

By leveraging voice coil motors, these systems effectively suppress low-frequency vibrations that typically degrade imaging quality.

The future of quantum-grade stabilization platforms looks promising with machine learning integration on the horizon.

These AI enhancements will enable real-time optimization of vibration suppression tailored specifically to your unique laboratory environment and imaging applications.

Nano-Scale Dampening Materials

While traditional vibration control systems continue to evolve, nano-scale dampening materials represent a revolutionary advancement in laboratory imaging stability.

You’ll find these innovative composites can enhance your active vibration control systems by up to 50% when targeting problematic low-frequency vibrations.

When implementing these materials in your lab photography setup, consider:

- Integration with microscopy and optical detection systems to minimize motion artifacts

- Replacement of bulkier stabilization components with lightweight nano alternatives

- Preparation for upcoming smart nano-dampening solutions that adaptively respond to varying frequencies

The compact nature of nano-scale dampening materials provides significant space savings in your laboratory environment while delivering superior performance.

As these technologies continue to mature, you’ll benefit from increasingly intelligent systems that automatically adjust to maintain ideal imaging conditions in real-time.

Frequently Asked Questions

What Is the Application of Active Vibration Control?

Active vibration control enhances your lab photography by reducing equipment movement in real-time. You’ll achieve clearer images as the system detects and cancels vibrations across all six degrees of freedom automatically.

What Does Vibration Control Do?

Vibration control reduces unwanted movements that affect precision equipment. You’ll see clearer images and more accurate data when vibration is minimized. It’s essential for sensitive instruments where even tiny movements can compromise results.

What Is the Difference Between Active and Passive Vibration Control Systems?

Active vibration control systems use sensors and actuators to counteract vibrations in real-time, while passive systems rely on springs and dampers. You’ll find active systems provide superior low-frequency isolation but cost more than passive alternatives.

How Does Active Vibration Isolation Work?

Active isolation works by detecting vibrations through sensors, then instantly creating opposing forces. You’ll find it uses feedback control to counteract disturbances in real-time, giving you superior performance for low-frequency vibrations.

In Summary

You’ll find active vibration control is an essential investment for your high-resolution lab photography. It’ll eliminate microscopic movements that passive systems can’t address, resulting in sharper images and more reliable data. As technologies advance, you’re likely to see even more sophisticated solutions that integrate with your existing equipment. Don’t compromise your research quality—implement active vibration control for immediately noticeable improvements.

Leave a Reply